High-Quality Parts With Speed and Precision

Flexibility from prototyping to volume production with 3D printing

Making new things possible with 3D printing

Wide range of 3D printing technologies

Advanced plastic, metal and elastomeric materials

Complex geometries with

post-processing flexibility

Our 3D Printing Capabilities

Carbon® Digital Light Synthesis™ (DLS)

Carbon® Digital Light Synthesis™ is ideal for developing high-fidelity prototypes and functional parts with isotropic properties, complex geometries and excellent surface finishes. Parts manufactured with DLS possess similar strength and mechanical properties to those manufactured via injection molding.

Multi Jet Fusion (MJF)

Multi Jet Fusion is capable of generating functional, chemically-resistant and highly dense parts. This makes MJF ideal for watertight applications, enclosures and other parts that have complex assemblies.

Parts can also be printed in full color, allowing designers to test the aesthetics of a product without the lead times or costs of post-processing.

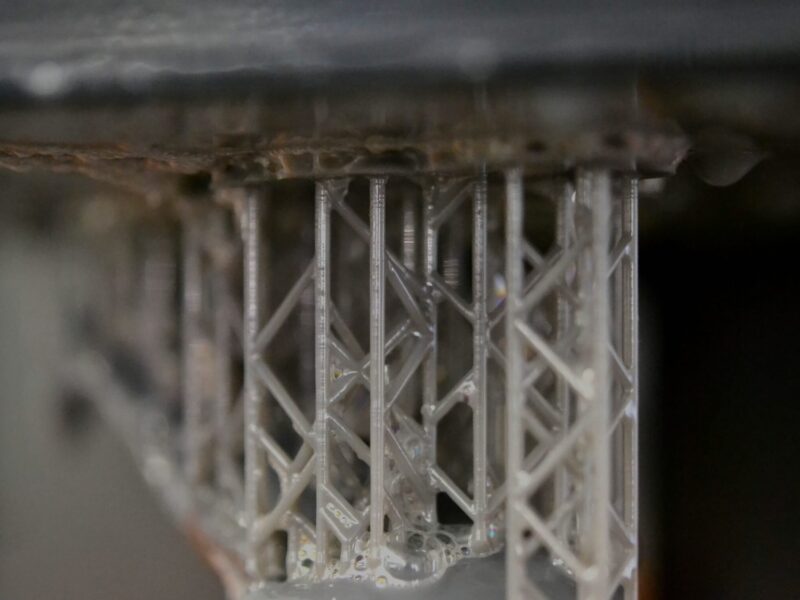

Fused Deposition Modeling (FDM)

Fused Deposition Modeling is one of the most frequently used additive technologies and is widely relied on for its ability to produce strong and cost-effective parts. FDM is also suitable for larger build sizes than other additive technologies.

Stereolithography (SLA)

Stereolithography is a tried-and-true additive manufacturing technology for many design and engineering teams. It’s fast, affordable and widely available. While SLA is not typically suitable for high-performance applications, its high-quality surface finishes and accurate detailing make it a popular option for prototypes.

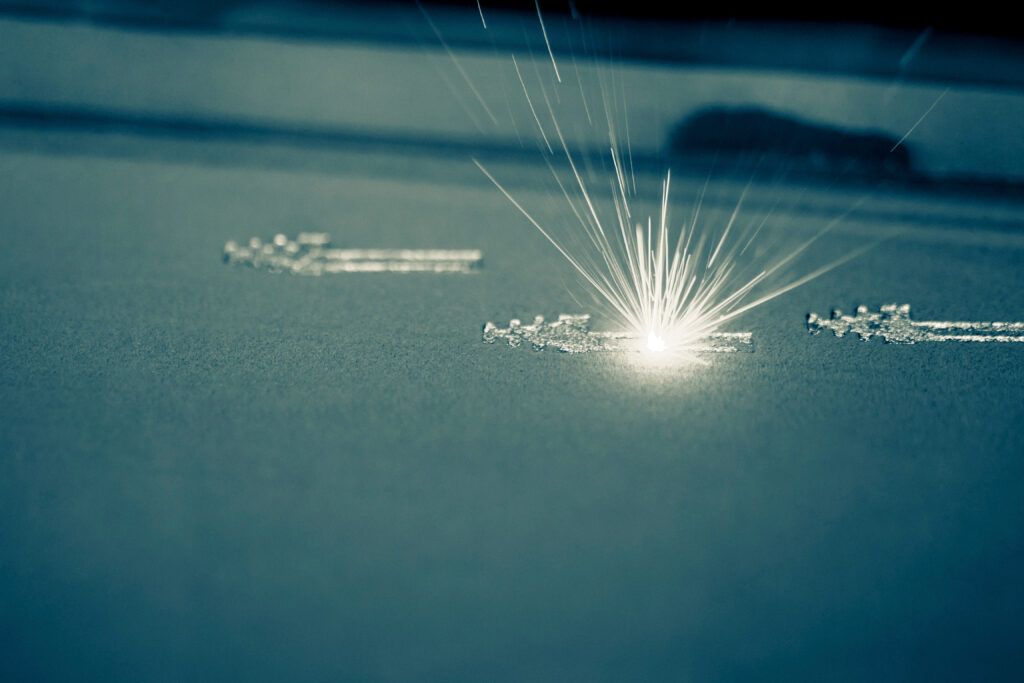

Direct Metal Laser Sintering (DMLS) and Selective Laser Melting (SLM)

Direct Metal Laser Sintering and Selective Laser Melting utilize high-powered lasers to selectively melt and fuse metal powder to produce parts with high levels of accuracy and tight dimensional tolerances. This technology creates parts with excellent durability and robust mechanical properties.

Extensive Material Options and Industry-Best Lead Times

SyBridge offers over 60 unique materials for 3D printing to meet the needs of any application.

| Technology | Materials | Lead Time |

|---|---|---|

| Digital Light Synthesis (DLS) | Rigid: CE 221, EPX 82, EPX 86 FR (Flame Retardant), FPU 50, IND 405, MPU 100 (biocompatible), RPU 70, RPU 130, UMA 90 Non-Rigid: EPU 40, EPU 41, IND 147 - HDT 230, SIL 30 | Typically four business days; expedited orders in as few as two business days |

| Multi Jet Fusion (MJF) | Standard: Nylon PA-11, Nylon PA-12, PA-12 GF, PP, and TPA Color: CB Nylon PA 12 | Four to five business days depending on material and color |

| Fused Deposition Modeling (FDM) | ABS-ESD7, ABS-M30, ABS-M30i, Antero 800NA (PEKK), Antero840CN03 (PEKK), ASA, Nylon PA-6, Nylon PA-12, Nylon PA-12 CF (Carbon-Filled), PC-10, PC-ABS, PC-ISO, PPSF, ST-130, Ultem 1010, Ultem 9085, Ultem 9085 CG | As few as three business days |

| Stereolithography (SLA) | Accura 25, Black, Color (multiple), Clear, Durable, Elastic, Flexible 80A, High Temp, Surgical Guide (biocompatible), Rigid 4000, Tough 1500, Tough 2000, White | As few as three business days for prototypes; production or high-volume runs are examined on a case-by-case basis |

| Direct Metal Laser Sintering (DMLS) / Selective Laser Melting (SLM) | Aluminum (AlSi10), Inconel 625, Inconel 718, Maraging Steel, Titanium (Ti64) | Custom quotes available on a case-by-case basis; lead times vary |

Typical 3D Printing Uses

Prototyping

3D printing offers unprecedented design versatility and the potential to manufacture parts using a variety of materials with speed and accuracy. Our 3D printing technologies are capable of achieving complex geometries and intricate dimensions without hard tooling or the production considerations of full manufacturing runs.

Low-Volume Production

3D printing is ideal for manufacturing small parts at low volumes, with cost advantages over traditional manufacturing processes as production scales up. With no capital expenses for tooling and no minimum order quantities, 3D printing processes are well suited to volume production in the hundreds or low thousands.

Custom Parts

3D printed designs can be customized quickly and at a very small scale for functionality and aesthetics — for example, adding textures, logos or serial numbers directly to parts without the need for post-processing.

3D Printing Guidebook