Making smarter construction possible

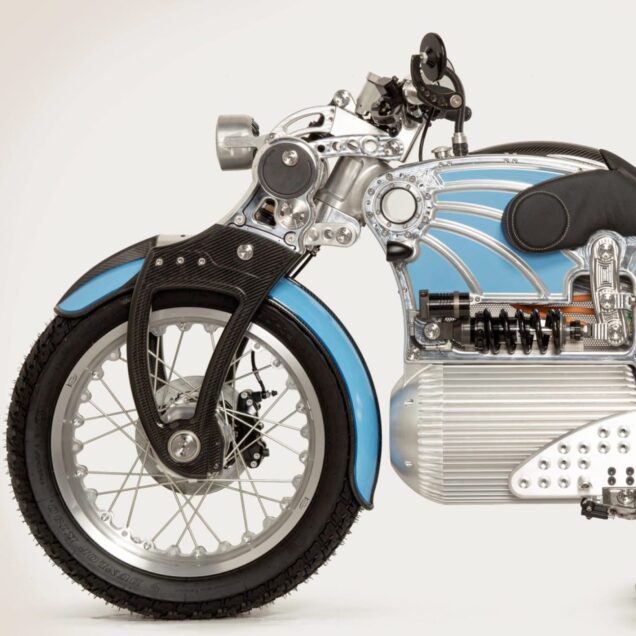

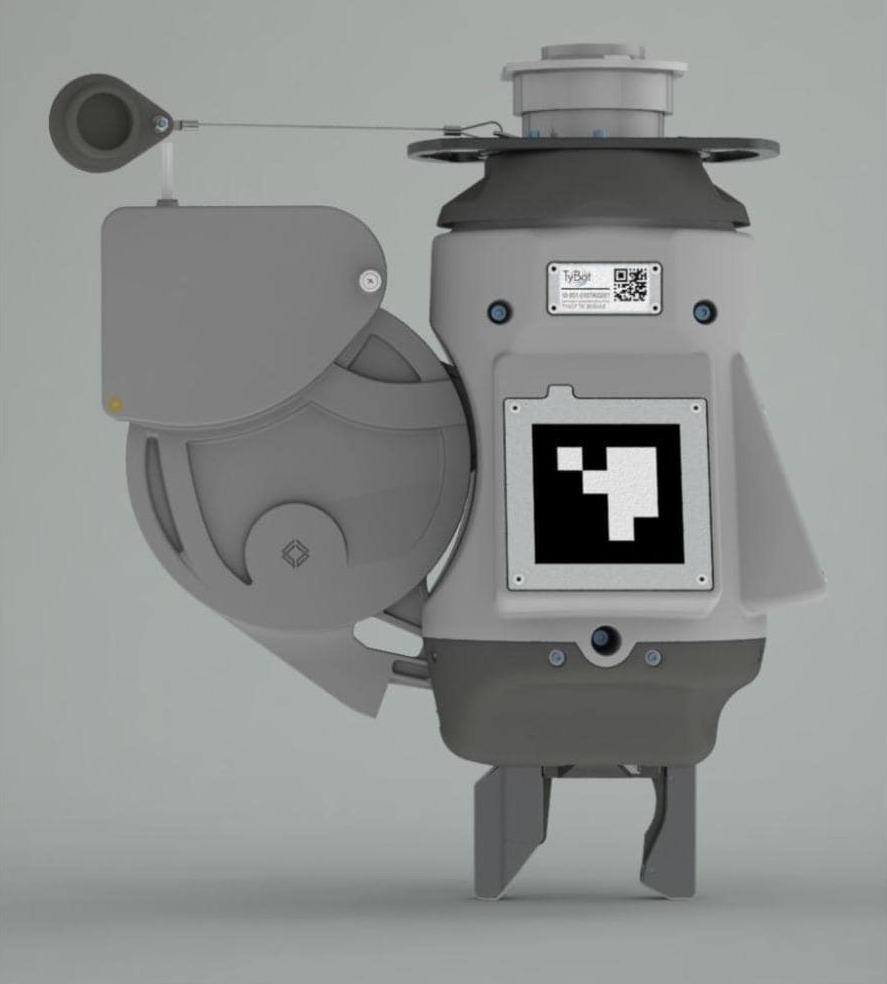

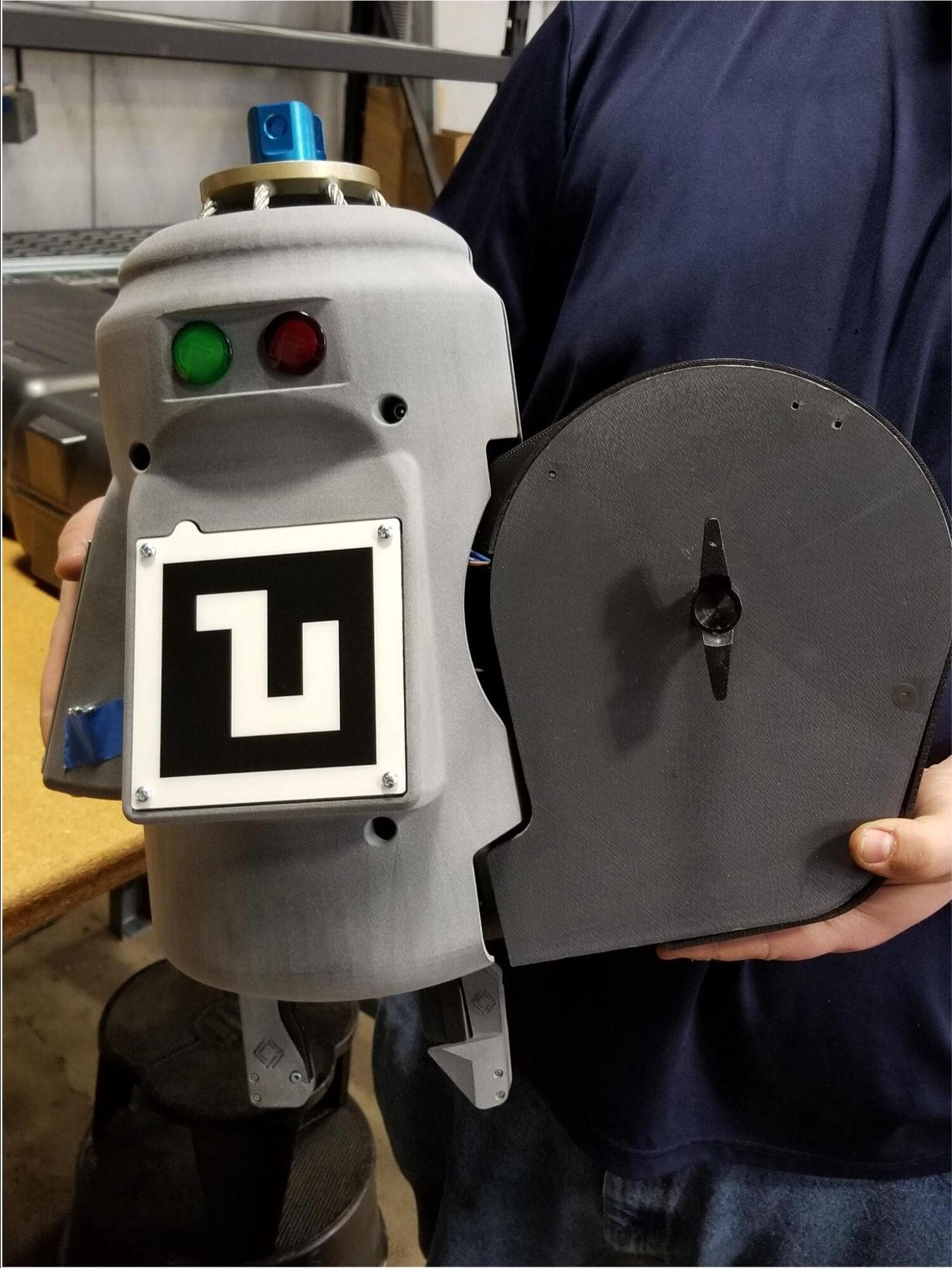

Advanced Construction Robotics (ACR) needed a reliable manufacturer for critical parts for their new rebar-tying robot, TyBot. With Fast Radius, they found a multi-process manufacturing partner to quickly scale their product and increase productivity and safety on job sites.

THE CHALLENGE

Building a scalable supply chain for a growing robotics startup

ACR came to Fast Radius to 3D print a small number of parts and found an ongoing multi-process manufacturing partner to streamline production for the majority of TyBot’s critical components.

When ACR came to Fast Radius, they were seeking a contract manufacturer to produce HP Multi Jet Fusion (MJF) parts for their TyBot prototypes. Impressed by Fast Radius’ quality standards and looking to scale quickly, ACR brought Fast Radius on to produce larger portions of their bill of materials across multiple manufacturing processes. Fast Radius provides MJF 3D printing, urethane casting, and CNC machining for ACR, making the housing and majority of the interior parts for the key module on their rebar-tying robot.

The robot’s parts interact directly with rebar, so they need to be able to withstand significant wear-and-tear in real-world use. Fast Radius was able to pivot with ACR, supporting production as they tried different materials and ultimately selected PA12 for TyBot’s outer housing and cast urethane for internal parts.

As a startup, ACR has moved through a number of iterations and field-testing cycles with TyBot. As TyBot has evolved, ACR has used the Fast Radius Virtual Warehouse™ to order parts on-demand in small batch sizes, mitigating waste and costs from product obsolescence and staying within production timelines for new and spare parts to maintain a universal fleet of robots.

Partnering with Fast Radius has helped ACR quickly scale production of TyBot while continuing to improve the robot’s performance without the costly time, resource, and manpower impact of multi-sourcing parts. By maintaining a lean and agile manufacturing partnership, Fast Radius has enabled ACR to effectively plan for the future.

The ability to single-source parts through Fast Radius has allowed us to turn up the knob on production because we can always count on getting high-quality parts. Having a partner that we can fully rely on has helped us grow our business without worrying about supply chain disruptions or delays.

MAKING IT POSSIBLE

A single trusted source for expanding multi-process needs

1. Multi-process expertise

ACR needed to simplify ordering, communication, and their supply chain. With CNC machining, HP MJF, and urethane casting capabilities, Fast Radius was the ideal partner. Having a single reliable source for the majority of their components made it easy for ACR to seamlessly streamline their TyBot part supply.

2. Steady supply chains

ACR first turned to Fast Radius for CNC machining after an overseas supplier delivered poorly manufactured parts that, after import fees, were more expensive than parts from Fast Radius. Since then, ACR has used Fast Radius for their ongoing CNC needs. In addition, as other manufacturers’ production capabilities have suffered from global supply chain issues, Fast Radius has been the only supplier ACR has been able to rely on for consistent production.

3. Low-volume production

With initial low-volume needs, ongoing design iterations, and new retrofitting and spare parts programs, the ability to manufacture low quantities at reasonable costs has helped ACR manage inventory and expenses as they grow production. In one situation, they were tasked with retrofitting a malfunctioning part for a customer on an aggressive timeline. Fast Radius was able to deliver the small batch of parts a week sooner than expected.

4. Reliable quality

As a single, trusted source for the majority of TyBot’s components, Fast Radius has enabled ACR to scale up without worrying about quality. First-article approval processes have allowed ACR to identify and resolve design flaws early, and Fast Radius’ high standards made it easy for ACR to name Fast Radius as a preferred vendor.

5. Dedicated customer support

For ACR, accessible support is critical. With dedicated Fast Radius resources, it’s always simple to ask questions, quote projects, and make important decisions quickly. Open lines of communication and a true partnership have kept projects on time and on budget and helped ACR accurately plan for future growth. While many manufacturers make it difficult to get support, with Fast Radius, ACR can get in touch with experts whenever they need.

THE RESULTS

Scaling a startup with a reliable supplier for critical components

3

manufacturing processes with one point of contact

45%

custom-engineered components made by Fast Radius

80

parts manufactured by Fast Radius in each TyBot

Gallery

Back

Back