Making engine envy possible

Evans Motorsport Performance (EMP) designed a specialty aftermarket part for the new Chevrolet Corvette C8. Demand for the part was high, but the acomplex design proved difficult and costly to manufacture. Fast Radius found EMP a solution that made low-volume production with automotive-quality materials feasible.

THE CHALLENGE

Giving Corvette C8 owners confidence to pop the engine bonnet

EMP had a workable design and plenty of demand for an after-market strut tower cover for the new Corvette C8, but they struggled to find a way to make it reliably within their budget.

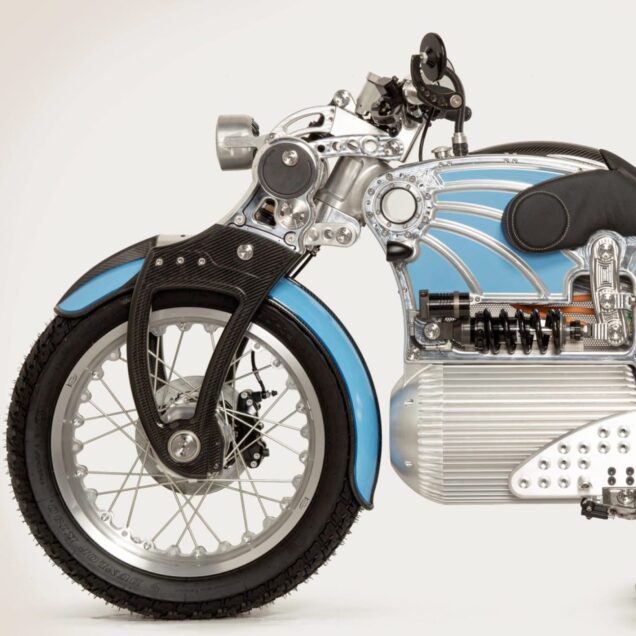

Evans Motorsport Performance builds custom performance parts for S550 Mustangs and C8 Corvettes. The new Corvette C8 presented a new challenge for them. Corvette owners understandably want to show off their engines, but the C8 has a rusted bolt on top of the strut tower cover that detracts from the appearance of the engine. A customer came to EMP asking for a cover for the bolt, and EMP recognized an opportunity to solve a problem for C8 owners.

The strut tower is an unattractive, complex piece to cover, but EMP deftly created a design after 3D scanning the area. Then they made a few prototypes using Fused Deposition Modeling (FDM) that impressed their original customer. EMP planned to machine the cover out of aluminum, but the part’s complexity made it difficult — if not impossible — to make. Even if they were able to machine the part, it was prohibitively expensive. Plus, EMP wanted to be able to offer custom colors and a modification for Mag-Ride Corvettes (which involved drilling a hole), both of which would be time-consuming and costly to do with aluminum. Next, they tried to make end-use parts with their prototyping printer but soon realized they couldn’t get the performance they needed.

That’s when EMP turned to Fast Radius. After evaluating several 3D printing processes and materials with Fast Radius, EMP settled on the Carbon Digital Light Synthesis (DLS)™ process and EPX 82. Fast Radius printed a single prototype for EMP that fit over the strut tower perfectly, and the two companies moved into production immediately. The part has proven extremely popular with Corvette C8 owners, and EMP is now selling the part through suppliers and distributors in the US and around the world. They plan to continue collaboration with Fast Radius on even more parts in their catalog.

We were amazed at the customer service, speed, and price we got with Fast Radius — not to mention the complexity we could achieve with the Carbon DLSTM process. Without Fast Radius we wouldn’t have been able to make this part.

MAKING IT POSSIBLE

Reliable production and high-performance materials

1. Economical low-volume production

EMP originally planned to machine the part from aluminum, but because of its complex design, the part would be prohibitively expensive, coming in at more than $4800 a set. Injection molding would have a cheaper cost per part, but only if they made enough to offset the cost of the molds, which could cost tens of thousands of dollars. Together, EMP and Fast Radius spent about a month and a half evaluating different additive processes before settling on the Carbon DLS process. DLS allowed EMP to create high-quality parts well within their budget, even for a small initial production run.

2. Reliable manufacturing process

The part EMP designed is quite complex. When they looked into machining it, there was a high risk that many of the parts would fail. Because the entire Carbon DLS process is completely digital, it produces identical, reliable parts every time. With DLS, EMP could rest assured Fast Radius would make all their parts consistently to spec.

3. High-performance materials

While the bolt cover is a cosmetic part that doesn’t affect the car’s performance, it needs to withstand temperatures approaching 200˚ F. After ruling out CNC and injection molding as viable manufacturing options, EMP tried to produce the parts with their prototype 3D printer. The available materials (PLA and ABS) could not withstand harsh engine conditions. After looking into several materials, Fast Radius suggested EPX 82, a rigid material popular in the auto industry for its heat and chemical resistance. EPX 82 provided the performance EMP required and was much easier to finish and paint than aluminum.

4. Rapid on-demand manufacturing

Had EMP opted to machine the parts, the initial order would have taken months to finish. The Carbon DLS process is much faster — Fast Radius printed and shipped EMP’s order in a matter of days. The part is new to the market, so EMP is still feeling out demand. With the Fast Radius Virtual Warehouse, EMP can store the part design in the cloud and order parts as they need them without worrying about running out of stock or holding excess inventory.

THE RESULTS

A part that makes a high-performance engine look even better

Thousands

Saved per part over CNC machining

$12

Thousand

Saved on tooling

5 days

To produce an entire production run

Gallery

Back

Back