Computer-Controlled Manufacturing

Taking your parts from prototype to production with precision and speed

Versatility and repeatability for diverse applications

Turning, drilling and

multi-axis milling

Extensive material options and fast lead times

Precision tolerances to

+/-0.001 inches

Industry-Leading CNC Machining Capabilities

3-Axis Milling

3-axis CNC milling involves cutting along three linear axes: left-to-right, back-and-forth, up-and-down. Easy to program and operate, 3-axis mills are effective for simple geometric designs and can be used for a wide variety of parts.

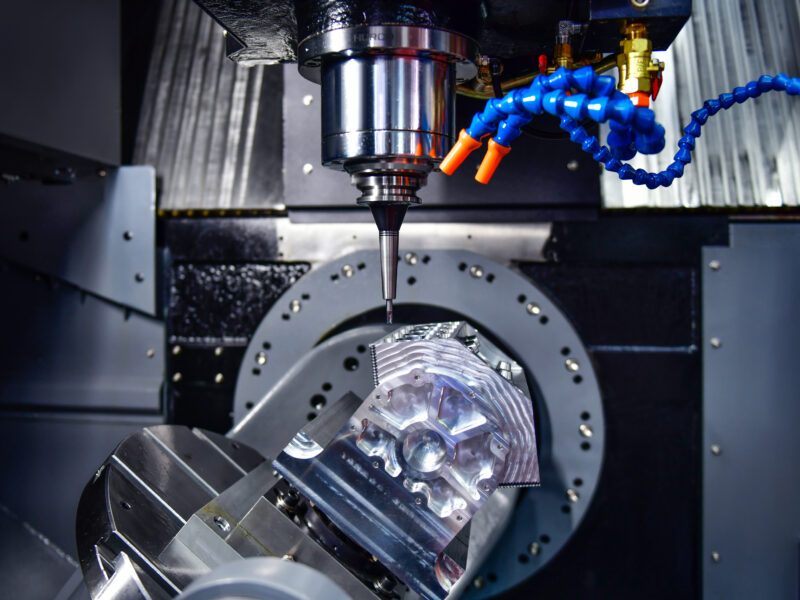

5-Axis Milling

5-axis CNC milling expands the design potential of the machining process by adding two axes of movement. With no need to reposition between operations, 5-axis milling allows for faster production of more complex parts.

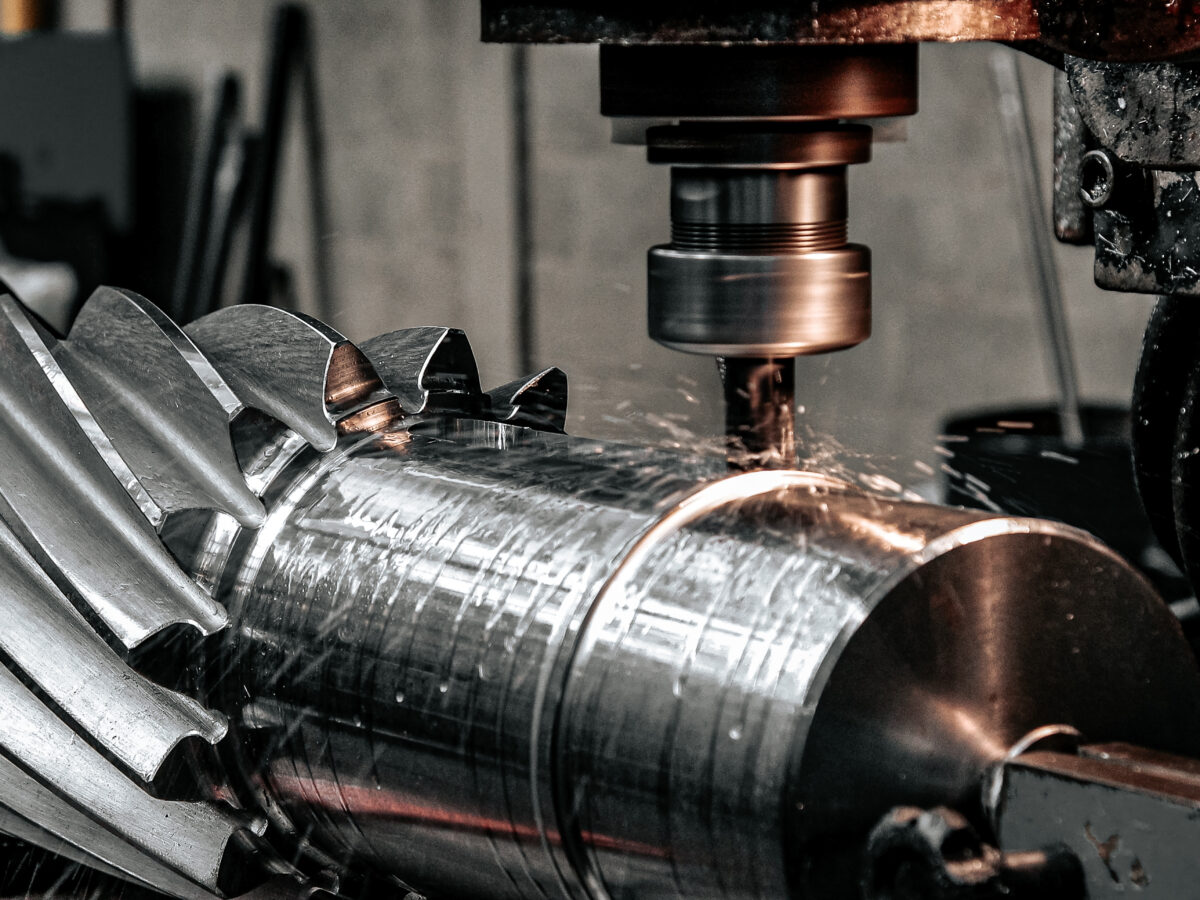

CNC Turning

CNC turning involves the application of a cutting tool to a rotating blank workpiece in order to shape a desired part. During production, the workpiece spins on vertical or horizontal axes while the automated lathe moves around it. Precise, repeatable and scalable, CNC turning is ideal for creating parts with simple geometries in rounded or cylindrical shapes.

Extensive Material Options and Industry-Best Lead Times

CNC machining offers incredible versatility in material selection, with a wide range of plastics and metals to choose from.

| Technology | Materials | Lead Time |

|---|---|---|

| CNC Machining | Plastic: ABS, Acetal (Delrin), Nylon 6, Nylon 30%GF, HDPE, PEEK, PC, PTFE (Teflon), PVC, UHMW Metal: Aluminum (2024, 6061, 6082, 7050, 7075), Stainless Steel (303, 304, 316, 17-4, 420), Other Steel (Mild Steel, Alloy Steel, Tool Steel), Other Metals (Brass, Copper, Titanium) | Eight to 10 business days for orders of <50 parts |

Typical CNC Machining Uses

Rapid CNC Prototyping

Create prototypes with high dimensional accuracy and excellent mechanical properties from a variety of metals and plastics leveraging our state-of-the-art CNC mills and lathes.

Custom Manufacturing

Produce precision parts from a wide range of materials, achieving tight tolerances, rapid production times and high repeatability.

Tooling and Fixtures

Manufacture tooling and fixtures to securely hold and position workpieces during manufacturing processes, ensuring accuracy and repeatability.

CNC Guidebook