Take 10% off your first order of Carbon DLSTM parts

We love showing new customers what we can make possible for them.

Carbon Production Network partner

The Carbon Production Network is an ecosystem of leading industry design firms and contract manufacturers who are experts in Carbon technology. Fast Radius is certified in using the Carbon platform – from design through production.

Get an instant quote for your Carbon DLSTM parts

Quoting is simple with Fast Radius.

Carbon DLS™ case studies

We are trusted by

Common Carbon DLS™ applications

Carbon DLS™ is often used for end-use parts because it produces high tolerances and smooth surface finishes. The speed of the Carbon DLS™ 3D printing process makes it an attractive option for rapid prototyping.

High-volume production runs

Cost-effective and quick production of small parts.

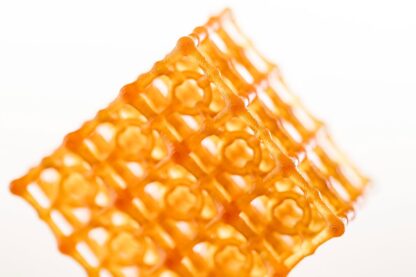

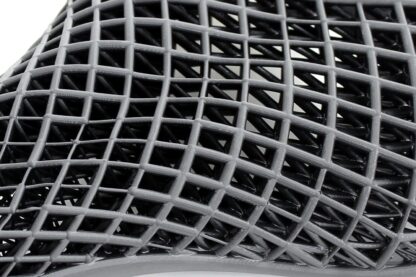

Foam replacement

Elastomeric lattice design enables custom mechanical responses.

Functional prototyping

Durable prototypes suitable for testing in real-world conditions.

Chemical and heat resistant parts

Materials that meet many functional and regulatory requirements.

Complex parts

Process allows geometries that would be impossible with other methods.

Why choose Fast Radius for 3D printing?

The factory of the future

The Fast Radius Cloud Manufacturing Platform™ combines digital design technology with the expertise of our team to make your project possible. Design your parts in the cloud, and ship on demand from our Virtual Warehouse™.

Back

Back