Making beautiful music possible

ClarinetXpress needed to find a way to make high-performing clarinet mouthpieces for elite musicians after they lost a trusted supplier. Fast Radius helped them leverage the unique benefits of additive manufacturing to find a long-term production solution.

THE CHALLENGE

Improving design, manufacturing, and fulfillment with additive manufacturing

After losing their longtime CNC supplier, ClarinetXpress struggled to find a partner who could meet their expectations for quality and turnaround time.

World-renowned clarinet technician and authority Walter Grabner founded ClarinetXpress more than 20 years ago to bring professional-grade clarinet mouthpieces to musicians around the world. His mouthpieces have made music in venues like Carnegie Hall and the Sydney Opera House. For years, ClarinetXpress products were made by a skilled machinist in Germany. When this manufacturing partner decided to retire, ClarinetXpress needed to quickly find another way to make their mouthpieces.

They tried other CNC machining providers first, but they took too long to deliver prototypes and none could produce the quality needed. That’s when ClarinetXpress decided to try additive manufacturing.

Their first attempt at 3D printing didn’t produce acceptable results, so they turned to Fast Radius. By taking advantage of Fast Radius’s design expertise and the unique benefits of additive manufacturing, ClarinetXpress improved its design, manufacturing, and fulfillment processes.

The capacity to produce prototypes quickly is invaluable to me. Being able to make quick changes and alterations to my mouthpieces has allowed me to deliver an exceptional product to my customers.

MAKING IT POSSIBLE

Additive manufacturing breathes new life into musical instrument production

1. Engineering expertise

ClarinetXpress tried other 3D printing companies, but the resulting mouthpieces did not look or feel smooth enough. Determined to find a better solution, the application engineers at Fast Radius sat down with Grabner to understand his performance and aesthetic requirements. They determined that Rigid Polyurethane (RPU 70) printed on Carbon® Digital Light Synthesis™ (DLS™) technology would give the mouthpieces the right look, feel, and sound.

2. Rapid prototyping

ClarinetXpress and Fast Radius went through several rounds of rapid prototyping within a few weeks. Making a single prototype with their former supplier would have taken at least a month. At each step in the process, the Fast Radius team helped ClarinetXpress optimize their designs for Carbon technology. Now that ClarinetXpress is more familiar with designing for additive manufacturing, they can prototype even faster.

3. Reliability and repeatability

Even the tiniest variation in a mouthpiece can alter the sound of a clarinet drastically. Mouthpieces need to meet precise specifications to achieve the quality and pitch demanded by elite musicians. With additive manufacturing, ClarinetXpress produces parts that meet these requirements, down to one hundredth of a millimeter in some cases. This makes more uniform products than ClarinetXpress achieved with CNC because Carbon DLS technology uses the same digital design to make identical parts every time.

4. Customization

ClarinetXpress can customize their products much more easily with additive manufacturing. With CNC, each mouthpiece had to be stamped or hand engraved with their logo after it was fabricated. With additive, ClarinetXpress prints the logo right on the part, eliminating the headache and cost of managing another step in the production process.

5. Low volume production and the virtual warehouse

When making a small number of parts, the economics of legacy manufacturing methods don’t always add up. ClarinetXpress frequently needs a relatively low volume of mouthpieces, comprising several different types and sizes. Where legacy processes would likely require them to order a large minimum number of each mouthpiece, additive allows them to order only as many as needed, without incurring extra cost. This approach creates a Virtual Warehouse™ for ClarinetXpress; instead of ordering mouthpieces in bulk and storing them, they can now place orders for small batches to meet immediate demand.

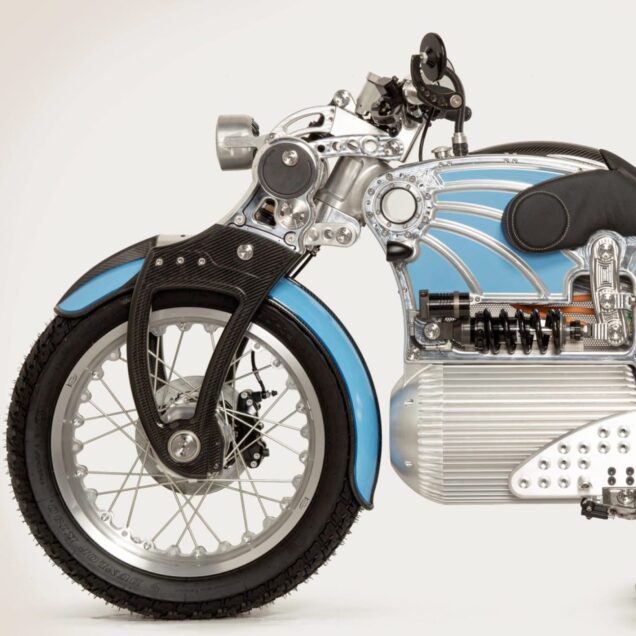

Gallery

THE RESULTS

A long-term solution for quickly and reliably producing high-quality, customized clarinet mouthpieces

Faster

Prototyping

Enhanced

Reliability and repeatability

Greater

Customization

Back

Back