Delivering Design and Manufacturing Excellence

Solutions for automotive, electric vehicles and industrial applications

Design, production and maintenance expertise for every stage of development

Expertise from design to after-market support

Full range of try-out, process and validation services

Comprehensive lighting commodity portfolio

Mobility & Industrial Specializations

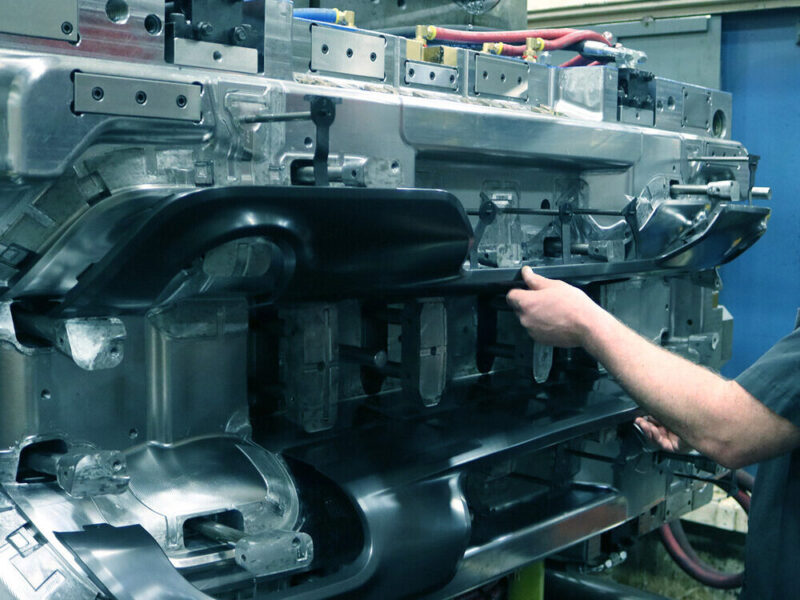

Mold Making

- Centralized design team

- FEA, mold flow and cooling analysis

- Fascias, grilles and lighting

Supportive Molding

- Presses from 140 to 4,000 tons

- Full try-out capabilities

- Process development and validation

Reliability Services

- Engineering changes and mold repair

- Logistics and supply chain support

- Customizable maintenance plans

Mobility & Industrial End-Use Applications

Automotive Mechanicals & Exterior Components

Automotive Interior

Components

Electric Vehicle

Components

Robotics & Industrial

Automation

Facilities at a Glance

| | Ontario, Canada | Puebla, Mexico |

|---|---|---|

| Manufacturing Facility | 185,000 sq. ft | 31,000 sq. ft |

| Molding Machines | 140 to 4,000 tons | 500 to 1,800 tons |

| CNC Machining | Hard Milling, Rough Milling, Turning/Lathe, Wire EDM, Sinker EDM, Surface Grinding, ID/OD Grinding | Hard Milling, Rough Milling, Turning/Lathe, Wire EDM, Sinker EDM, Surface Grinding, ID/OD Grinding |

| Reflex Tooling and Lighting | Yes | Yes |