Making faster automotive innovation possible

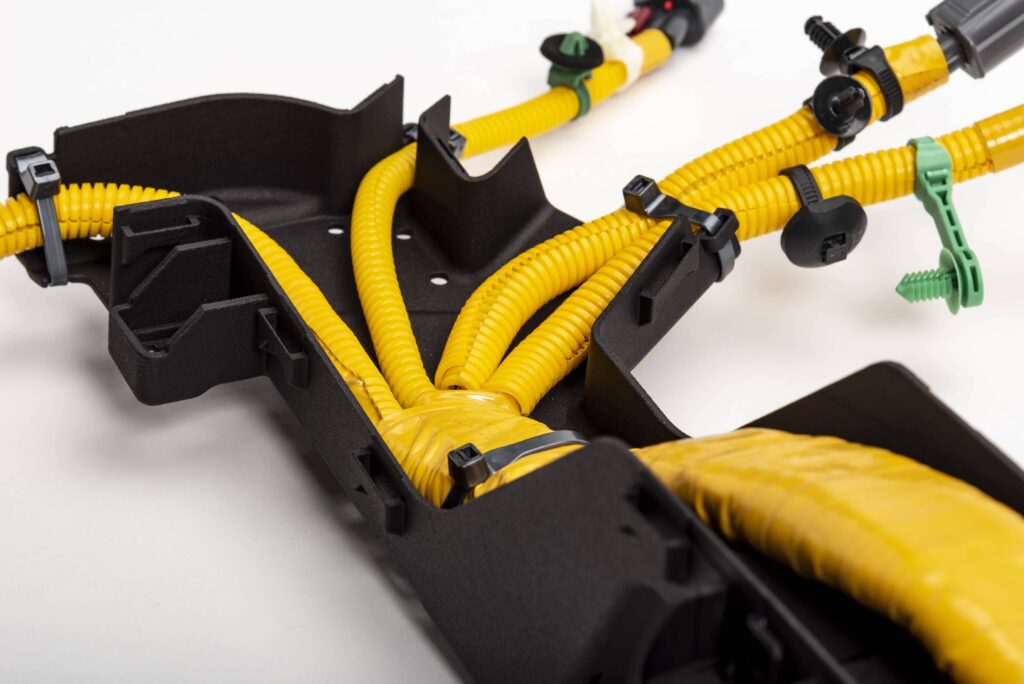

HellermannTyton needed to manufacture a package of wire routing aids for a prototype vehicle. These parts were large and complex, even for additive manufacturing, and the company was faced with a restricted timeline to meet customer demand. Fast Radius rose to the challenge and helped HellermannTyton produce plastic parts quickly.

THE CHALLENGE

Meeting tier one automotive expectations

HellermannTyton is a leader in designing and manufacturing cable management products. When automotive OEMs want innovative wire harness solutions, they turn to HellermannTyton. When the company came up against a project that required additive manufacturing and fast timelines, they turned to Fast Radius.

HellermannTyton was tasked by a tier one automotive company with manufacturing a series of wire routing aids for a new prototype vehicle. The plastic wire routing aids help mount and guide the wire harnesses throughout the vehicle’s interior, ensuring that electrical wires are safely secured. Due to the large size and complexity of these parts, HellermannTyton needed to modify the designs by splitting them into two to four smaller sections that could be produced within the machine’s build volume. The sections themselves aren’t small; each one could measure nearly 13 inches with the final assembly coming out at nearly 46 inches.

Typically, large plastic parts are a perfect fit for production injection molding. But this was a low-volume run, which meant that injection molding would be too costly. Not to mention, the team had exactly six weeks to produce over 1000 parts for the first run. HellermannTyton teamed up with Fast Radius to tap into their additive manufacturing capabilities needed and to meet the rigorous demands of the project.

We like working with Fast Radius because they truly understand the needs of automotive companies. When it comes to this industry, Fast Radius knows what best-in-class looks like and how to deliver the parts we expect.

MAKING IT POSSIBLE

Powerful production capacity and expertise

1. HP Multi Jet Fusion (MJF) capabilities

The combination of fast lead times, low-volume runs, and complex assemblage made additive manufacturing the right choice for production. However, it was important that the technology used to manufacture the routing aids had the right build capacity and materials to meet quality requirements. Because of these considerations, HellermannTyton chose HP MJF and PA12 for the project. Fast Radius had the production capacity through both their own fleet of HP MJF machines and their network of partners to meet the project’s lightning-fast timelines. This saved HellermannTyton time and costs by using Fast Radius as a one-stop shop for all of their MJF needs.

2. Simplified post-production and assembly

Each routing aid is custom-built to match the internal framework of the vehicle. The components have complex geometries that require assembly to the wiring harness. HellermannTyton worked with Fast Radius to print sections with mating geometry that when used in combination with adhesive creates a reliable finished product. Fast Radius’ on-site factory tech team worked closely with HellermannTyton to deliver on the post-processing requirements, which included part dyeing, assembly, and specialized shipping. The parts also had a very high success rate thanks to Fast Radius’ extensive experience in manufacturing with HP MJF.

3. Agile and fast partnership

As the automotive industry continues to evolve and innovate, fast project timelines are becoming the norm. Fast Radius had six weeks to deliver the first few thousand parts. While some manufacturing partners would balk at that timeline, Fast Radius got right to work, ensuring the parts would be delivered on time at a very affordable cost. Fast Radius prides itself on being a true partner, flexible and quick so HellermannTyton could produce a big win with their customer.

4. Reduced costs and lead times

HellermannTyton was able to eliminate the upfront cost of injection molding tooling and trials for the customer. It’s estimated that 3D printing saved nearly $1 million. Partnering with Fast Radius for additive manufacturing enabled HellermannTyton to meet the very fast lead time their customer required; the teams were able to save nearly two months in typical project lead time.

Gallery

THE RESULTS

Additive manufacturing with Fast Radius saved HellermannTyton time and money

8 weeks

saved in lead time

$950K

saved in project costs

1,235 parts

assembled from 3,055 sections in 6 weeks

Ready to make your parts with Fast Radius?

Making engine envy possible

Evans Motorsport Performance (EMP) designed a specialty aftermarket part for the new Chevrolet Corvette C8. Demand for the part was high, but the acomplex design proved difficult and costly to manufacture. Fast Radius found EMP a solution that made low-volume production with automotive-quality materials feasible.

THE CHALLENGE

Giving Corvette C8 owners confidence to pop the engine bonnet

EMP had a workable design and plenty of demand for an after-market strut tower cover for the new Corvette C8, but they struggled to find a way to make it reliably within their budget.

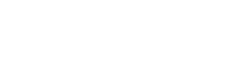

Evans Motorsport Performance builds custom performance parts for S550 Mustangs and C8 Corvettes. The new Corvette C8 presented a new challenge for them. Corvette owners understandably want to show off their engines, but the C8 has a rusted bolt on top of the strut tower cover that detracts from the appearance of the engine. A customer came to EMP asking for a cover for the bolt, and EMP recognized an opportunity to solve a problem for C8 owners.

The strut tower is an unattractive, complex piece to cover, but EMP deftly created a design after 3D scanning the area. Then they made a few prototypes using Fused Deposition Modeling (FDM) that impressed their original customer. EMP planned to machine the cover out of aluminum, but the part’s complexity made it difficult — if not impossible — to make. Even if they were able to machine the part, it was prohibitively expensive. Plus, EMP wanted to be able to offer custom colors and a modification for Mag-Ride Corvettes (which involved drilling a hole), both of which would be time-consuming and costly to do with aluminum. Next, they tried to make end-use parts with their prototyping printer but soon realized they couldn’t get the performance they needed.

That’s when EMP turned to Fast Radius. After evaluating several 3D printing processes and materials with Fast Radius, EMP settled on the Carbon Digital Light Synthesis (DLS)™ process and EPX 82. Fast Radius printed a single prototype for EMP that fit over the strut tower perfectly, and the two companies moved into production immediately. The part has proven extremely popular with Corvette C8 owners, and EMP is now selling the part through suppliers and distributors in the US and around the world. They plan to continue collaboration with Fast Radius on even more parts in their catalog.

We were amazed at the customer service, speed, and price we got with Fast Radius — not to mention the complexity we could achieve with the Carbon DLSTM process. Without Fast Radius we wouldn’t have been able to make this part.

MAKING IT POSSIBLE

Reliable production and high-performance materials

1. Economical low-volume production

EMP originally planned to machine the part from aluminum, but because of its complex design, the part would be prohibitively expensive, coming in at more than $4800 a set. Injection molding would have a cheaper cost per part, but only if they made enough to offset the cost of the molds, which could cost tens of thousands of dollars. Together, EMP and Fast Radius spent about a month and a half evaluating different additive processes before settling on the Carbon DLS process. DLS allowed EMP to create high-quality parts well within their budget, even for a small initial production run.

2. Reliable manufacturing process

The part EMP designed is quite complex. When they looked into machining it, there was a high risk that many of the parts would fail. Because the entire Carbon DLS process is completely digital, it produces identical, reliable parts every time. With DLS, EMP could rest assured Fast Radius would make all their parts consistently to spec.

3. High-performance materials

While the bolt cover is a cosmetic part that doesn’t affect the car’s performance, it needs to withstand temperatures approaching 200˚ F. After ruling out CNC and injection molding as viable manufacturing options, EMP tried to produce the parts with their prototype 3D printer. The available materials (PLA and ABS) could not withstand harsh engine conditions. After looking into several materials, Fast Radius suggested EPX 82, a rigid material popular in the auto industry for its heat and chemical resistance. EPX 82 provided the performance EMP required and was much easier to finish and paint than aluminum.

4. Rapid on-demand manufacturing

Had EMP opted to machine the parts, the initial order would have taken months to finish. The Carbon DLS process is much faster — Fast Radius printed and shipped EMP’s order in a matter of days. The part is new to the market, so EMP is still feeling out demand. With the Fast Radius Virtual Warehouse, EMP can store the part design in the cloud and order parts as they need them without worrying about running out of stock or holding excess inventory.

THE RESULTS

A part that makes a high-performance engine look even better

Thousands

Saved per part over CNC machining

$12

Thousand

Saved on tooling

5 days

To produce an entire production run

Gallery

Ready to make your parts with Fast Radius?

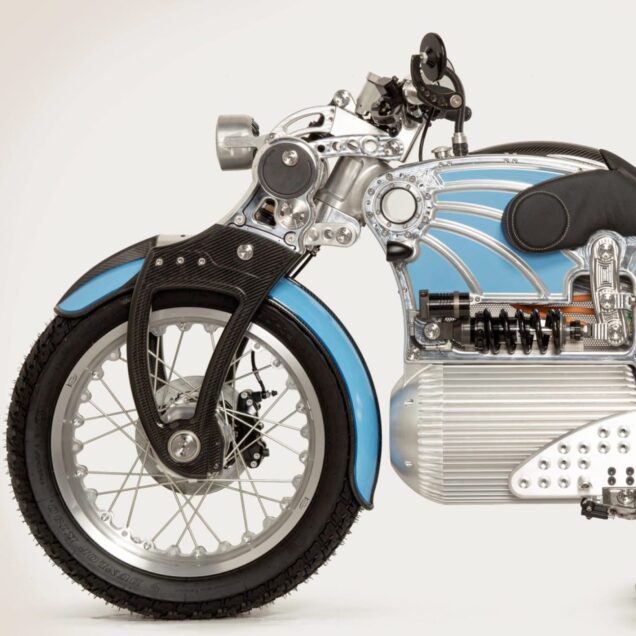

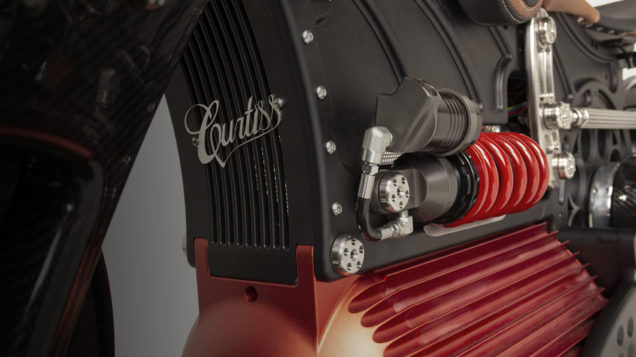

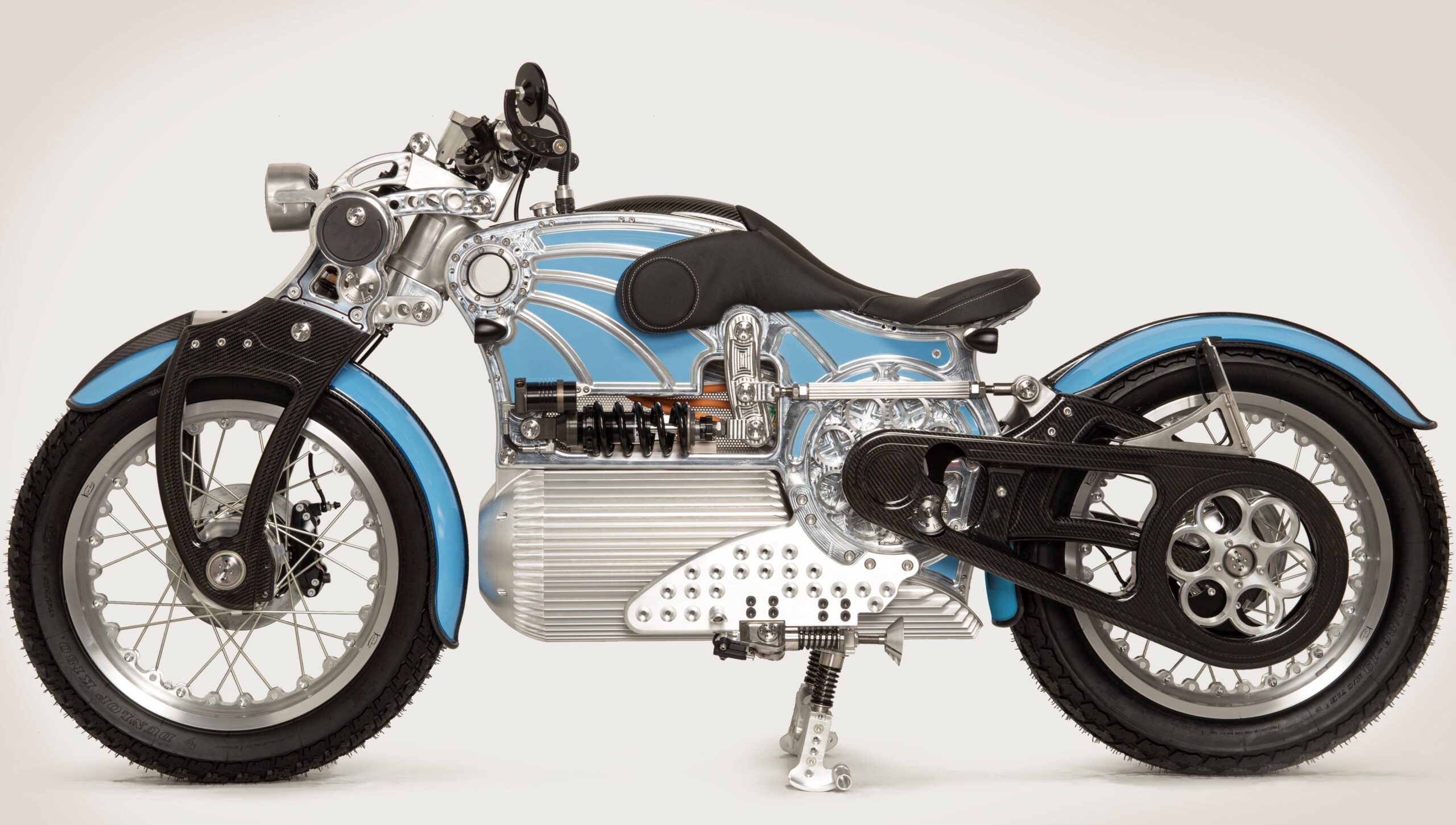

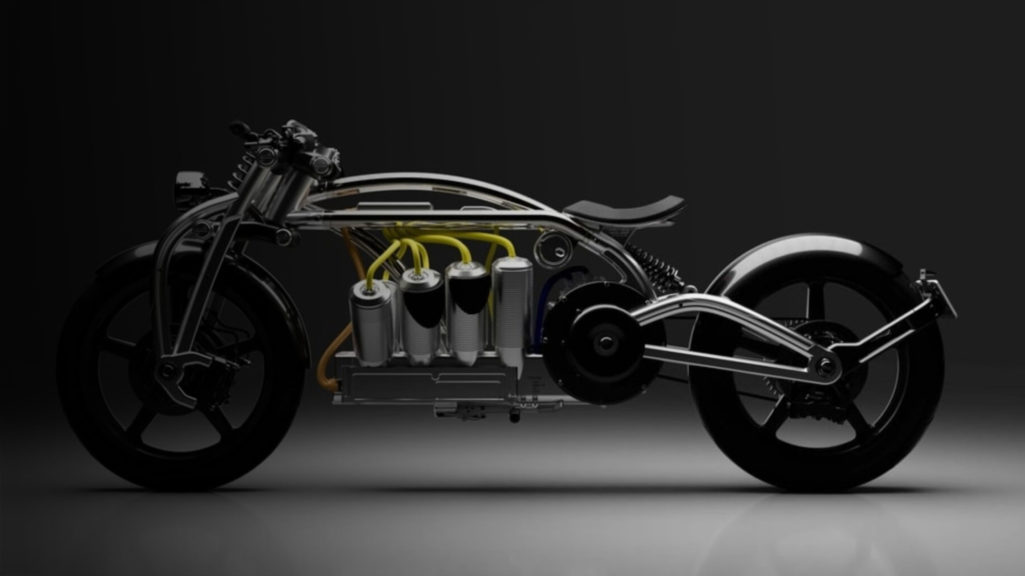

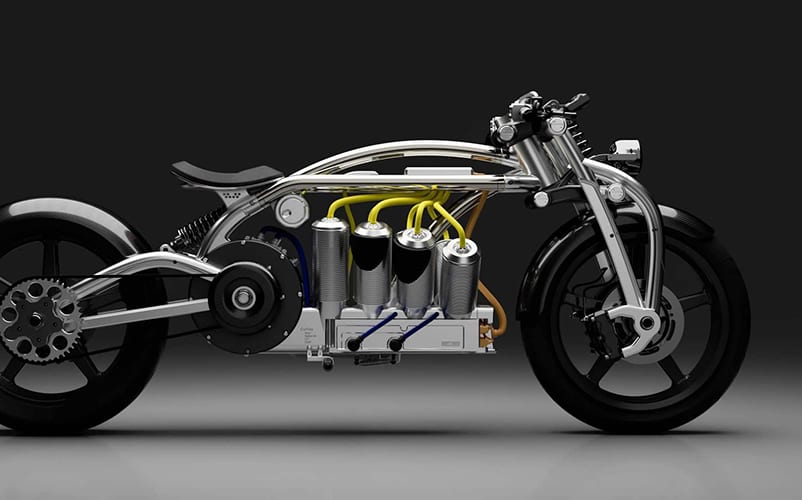

Making a trailblazing motorcycle possible

Curtiss reinvented the electric vehicle category with the Curtiss One, a luxury electric motorcycle with unparalleled performance and aesthetic appeal. Fast Radius provided innovative production and fulfillment solutions that allowed Curtiss to bring their vision to the world.

THE CHALLENGE

Producing a design-driven luxury electric motorcycle with the flexibility of on-demand manufacturing

Curtiss envisioned a revolutionary electric motorcycle, but struggled to find a manufacturing partner up to the challenge.

Curtiss designed an electric motorcycle unlike anything the world had ever seen, and they needed to unveil a prototype quickly. Fast Radius made their vision possible with multi-process manufacturing solutions.

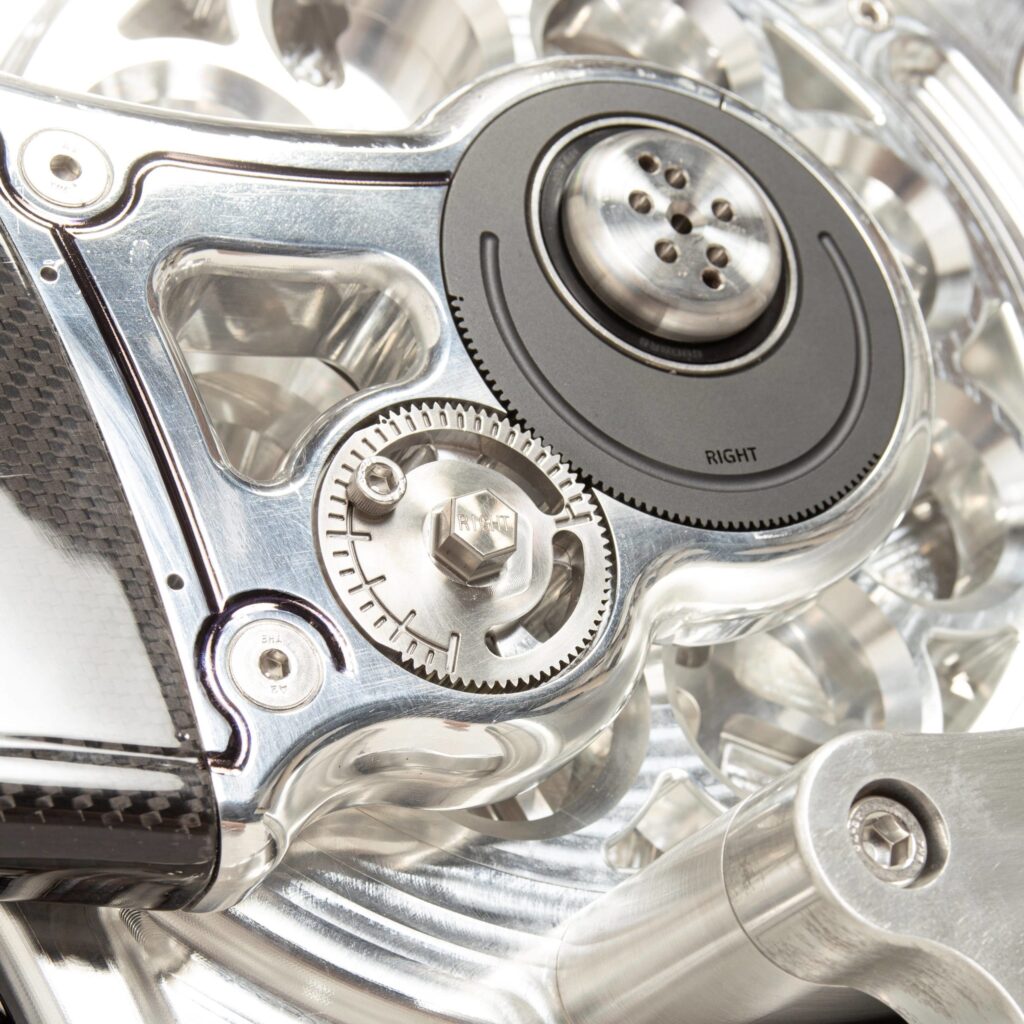

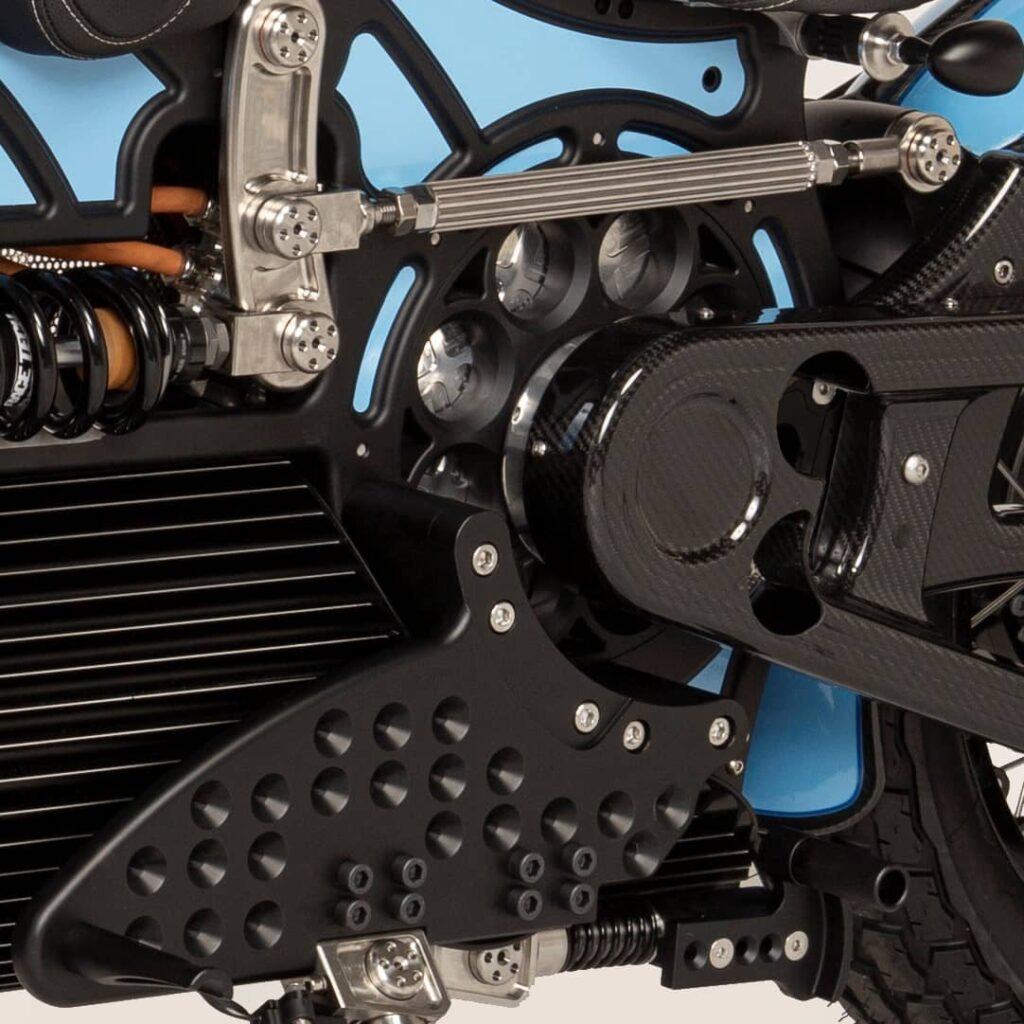

The Zeus 8 is an exceptionally beautiful bike. It has a sweeping chromoly frame and eight banks of sleek, visible battery cylinders. However beautiful, these large, complex parts proved difficult to manufacture. Curtiss’ CNC suppliers quoted long lead times and had trouble delivering on the uncompromising design and quality requirements. With the Zeus 8 launch event approaching, Curtiss needed a partner who could get the unique bike into production immediately.

Fast Radius allows our company to seamlessly expand to new models and segments as the market for EV motorcycles grows. With Fast Radius, turning around new designs and prototypes is faster and less expensive than with any other manufacturer. We’re able to outmaneuver large companies and plan for our future without worrying about scaling. We can’t thank Fast Radius enough for their partnership. The quality of the work they’ve done for us is unbelievable.

MAKING IT POSSIBLE

On-demand production and a flexible long-term partnership

1. Long-term production partnership

Fast Radius has a deep understanding of Curtiss’ business that goes beyond making all of Curtiss’ CNC and additive parts. Unlike a typical contract manufacturer, Fast Radius has visibility into the entire production process, making for a seamless ramp from concept to prototype to production.

2. On-demand manufacturing

Curtiss orders parts from Fast Radius as needed, eliminating the logistics and expenses of warehousing. Fast Radius is able to provide the cost efficiencies of large orders without forcing Curtiss to take delivery of all their parts at once. With Fast Radius, Curtiss can access flexible capacity to easily ramp up production as demand increases.

3. Economic efficiency

Fast Radius stuck to Curtiss’ budget, leveraging relationships with trusted production partners to get extremely competitive prices — even on expensive post-processing and anodization. To keep fulfillment costs down, Fast Radius devised strategic shipping solutions and payment terms. Since this is an ongoing project, Curtiss gets Fast Radius’ annual discounts for long-term production.

4. Hands-on project management

No single factory could make all the parts for the Curtiss One, so Fast Radius coordinated production within their global network. Fast Radius handles all project management and quality operations, ensuring Curtiss receives parts made to spec and on schedule. If issues arise — even with overseas suppliers — the Fast Radius project management team finds a solution, usually without having to involve Curtiss at all. On the front end, Fast Radius provides design for manufacturing (DFM) support, ensuring every part will be made correctly the first time.

Gallery

THE RESULTS

A partnership that’s transforming the motorcycle industry

160

parts per bike

90%

BOM made by Fast Radius

1 month

order cycles

Ready to make your parts with Fast Radius?

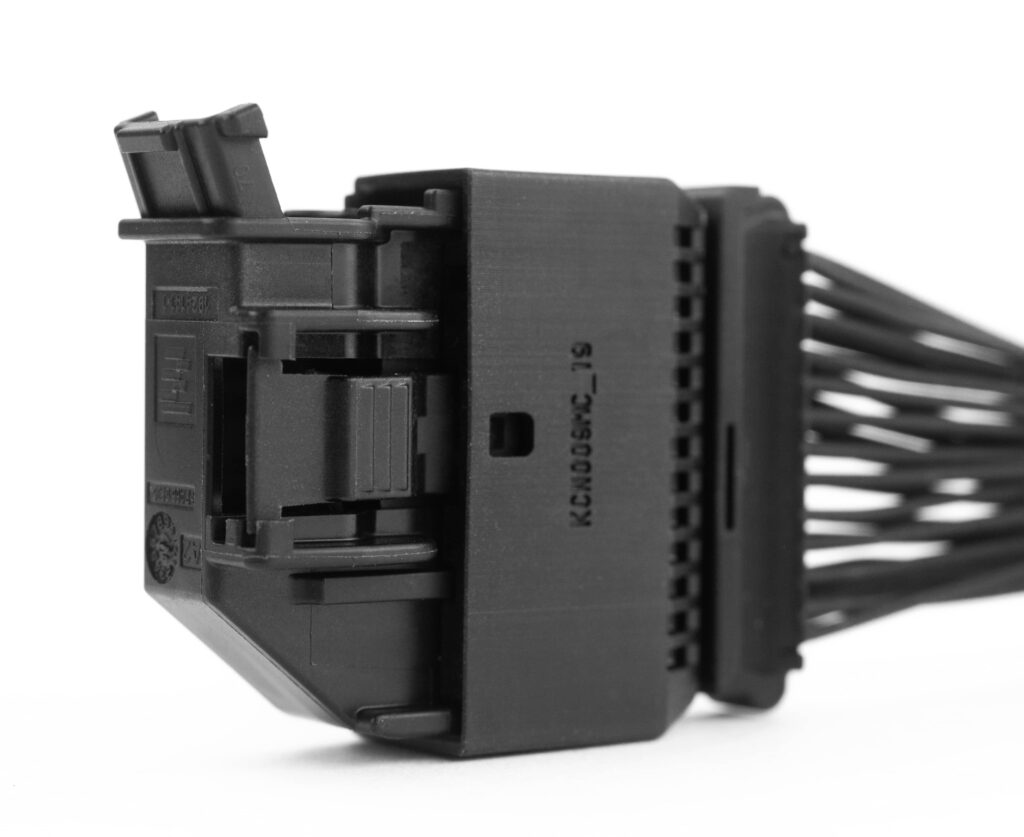

Making easy automotive diagnostics possible

TE Connectivity needed to manufacture a new electrical connector for a diagnostic module used by a major American automaker. Working with Fast Radius and Carbon®, they found a solution that produced end-use quality parts quickly, without the capital expenditure of injection molding.

THE CHALLENGE

Manufacturing an automotive-quality electrical connector quickly without major capital expenditures

TE Connectivity needed to make an automotive part quickly, in relatively small volumes using automotive-approved materials.

A major American automaker approached TE Connectivity with a challenge. They needed a connector for a fast-feedback diagnostic module meant to be used in several hundred cars at a time. In these small volumes, neither the automaker nor TE Connectivity could justify injection mold tooling costs, which might approach $100,000 for this part.

Moreover, the connector needed to be made with a durable, rigid, serial-grade plastic that could withstand real-world conditions and eventually pass an automotive part production approval process (PPAP). TE Connectivity knew how to design the optimal connector for their customer, but they needed a manufacturing partner who could produce a part that met their specifications.

Together, Carbon and Fast Radius made TE Connectivity’s vision a reality. With its ability to create durable parts using automotive-quality materials, the Carbon DLS™ process was the ideal way to make the connector. Fast Radius’ scalable DLS production capacity and extensive experience making end-use parts for the automotive industry allowed TE Connectivity to move into production quickly and efficiently.

The working relationship between our companies has made the program a success. Together, Fast Radius and Carbon were able to anticipate and solve all the design and manufacturing challenges that got in our way. The result is an auto-quality part that we can produce at scale.

MAKING IT POSSIBLE

Durable material and scalable production

1. Automotive-certified materials

TE Connectivity chose to make the connector with Carbon EPX 82 because of its rigidity, strength, and temperature resistance. Used extensively in the auto industry, EPX 82 has gone through USCAR testing, heat age cycling, fluid resistance tests, and has been approved for other serial automotive production parts. TE Connectivity was confident that EPX 82 would meet their customer’s stringent requirements.

2. Design freedom

TE Connectivity leveraged a couple key benefits of additive manufacturing in their design for the electrical connector. They serialized each part with a unique, digitally applied number, allowing each part to be fully traced through the supply chain. Printing the serial number directly on the part saves time since serial numbers typically have to be added after a part is molded or casted. TE Connectivity also simplified and improved the product design by incorporating performance features that could only be achieved with the DLS process.

3. Rapid iteration

TE Connectivity went through three rounds of iterations in just a few weeks before landing on the optimal design for the connector. With each round, Fast Radius produced new production-grade parts in a matter of days, rather than the weeks or months a similar revision would take with molding. Plus, each minor design alteration didn’t cost anything, whereas a new tool would cost thousands or even tens of thousands to alter. TE Connectivity’s customer was able to test these parts in the field much sooner than would be possible in a traditional product development cycle because the connectors are made with the same material and process as the end-use parts.

4. Scalable production capacity

TE Connectivity’s customer initially needs a few thousand electrical connectors made. This isn’t enough to justify the capital expenditure of an injection molding tool, but it’s more than a prototyping shop can handle. Fast Radius has a certified automotive-grade quality system and the manufacturing infrastructure required to make end-use production parts in any quantity. This allows TE Connectivity to scale production as their customer’s needs evolve. If demand for the product grows to the point where injection molding makes economic sense, Fast Radius can manage the entire bridge to tooling process as well.

THE RESULTS

A collaboration that makes automotive-quality parts faster, better, and less expensive.

$10,000

estimated savings in injection molding tooling

ISO 9001

certified quality management

No

minimum order quantity

Weeks

from concept to production, rather than months

Gallery

Ready to make your parts with Fast Radius?

Making riding in style possible

Curtiss had big plans to make an electric motorcycle unlike anything the world had ever seen. Fast Radius had comprehensive multi-process manufacturing solutions to make it possible.

THE CHALLENGE

Prototyping a game-changing electric motorcycle with advanced manufacturing

Curtiss envisioned a revolutionary electric motorcycle, but struggled to find a manufacturing partner up to the challenge.

Curtiss designed an electric motorcycle unlike anything the world had ever seen, and they needed to unveil a prototype quickly. Fast Radius made their vision possible with multi-process manufacturing solutions.

The Zeus 8 is an exceptionally beautiful bike. It has a sweeping chromoly frame and eight banks of sleek, visible battery cylinders. However beautiful, these large, complex parts proved difficult to manufacture. Curtiss’ CNC suppliers quoted long lead times and had trouble delivering on the uncompromising design and quality requirements. With the Zeus 8 launch event approaching, Curtiss needed a partner who could get the unique bike into production immediately.

We work with Fast Radius because they push us toward the cutting edge of manufacturing technology. We’re creating the most advanced motorcycles the world has ever seen, and Fast Radius is committed to making our vision a reality.

MAKING IT POSSIBLE

Advanced manufacturing expertise and next-level operational efficiency

1. Enhancing manufacturability

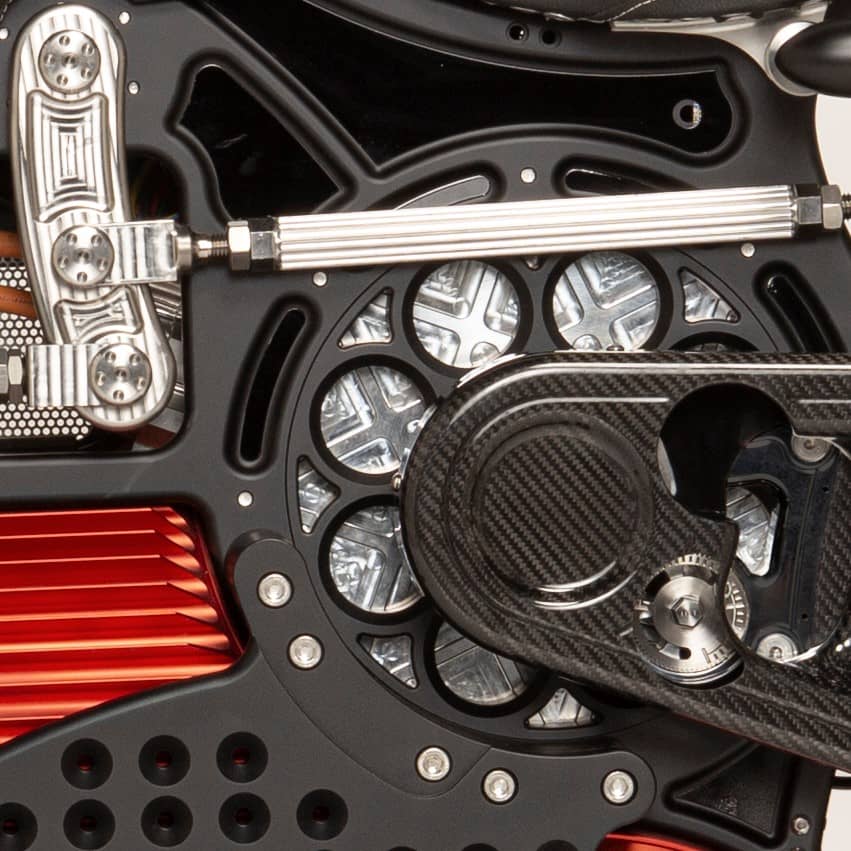

Fast Radius’s expert application engineers worked with Curtiss to optimize their designs for advanced manufacturing technology. Most CNC machines can’t create the large, sleek parts that make the Zeus 8 so distinctive, and making and assembling smaller pieces into a larger part wouldn’t give the bike the desired polished, dramatic look. The engineers at Fast Radius worked closely with Curtiss to solve this challenge. Together, they created manufacturable parts that still adhered to Curtiss’ high design standard.

2. Multi-process manufacturing

Fast Radius evaluated each component separately, and quickly determined that the Zeus could be made most efficiently with a multi-process manufacturing approach. The method used for the larger parts—in this case 5-axis CNC milling—wouldn’t make sense for the motorcycle’s many smaller parts. Rather than pushing Curtiss toward a single manufacturing process, the Fast Radius team evaluated all of the part requirements and created a solution comprising three separate production processes, including both legacy and additive methods.

3. Operational efficiency

After Curtiss and Fast Radius completed designs and chose the appropriate technology for each part, they immediately moved into production to meet Curtiss’ approaching deadline. Thanks to their lean manufacturing model and project management expertise, Fast Radius produced the parts in just 12 days, two days faster than any other supplier could offer. For the Zeus 8, Fast Radius produced 60 parts and components that maintained better than 95% first-pass yield, eliminating the need for costly part revisions.

4. The future of electric motorcycles

Curtiss is eager to innovate further with Fast Radius. The two companies are engaged in an ongoing partnership to make parts for the entire Curtiss line of luxury electric motorcycles. Fast Radius will continue to bring Curtiss’ show-stopping designs to life with the most innovative manufacturing methods available.

THE RESULTS

Groundbreaking electric motorcycles made possible by multi-process manufacturing

60

components

12 day

production time

95%+

first-pass yield

Gallery

Ready to make your parts with Fast Radius?

Making reliable automotive supply possible

Aptiv wanted an innovative supply chain solution for low-volume production for Ford, a leading American automaker. Fast Radius’s additive manufacturing expertise and Carbon®’s industrial-grade 3D printing technology helped Aptiv transition to an entirely new production method while still meeting rigorous quality standards.

THE CHALLENGE

Ensuring quality additive production for automotive suppliers

Aptiv is a leading technology provider, delivering safer, greener, more connected solutions that enable the future of mobility. They were responsible for the design and production of a trailer-tow connector cap for Ford Super Duty trucks to protect the electrical connectors from harsh environmental exposure.

To address this challenge, Aptiv wanted to push the boundaries of what’s possible in lower-volume, critical part production for a Ford trailer tow connector cap application and deliver a quality product that met Ford’s expectations for the best possible cost and speedy, flexible production.

The trailer-tow connector cap needed to meet the automotive industry’s standard engineering and quality requirements — specifically, USCAR-2 validation and ISO 9000 certification — to guarantee the protection of the electrical connector against external elements.

With these considerations in mind, Aptiv worked closely with Carbon, a leader in digital manufacturing technology and additive materials development, and Fast Radius, a manufacturing partner with expertise in repeatable, reliable additive production to make this possible.

Their combined efforts led to serial production of the trailer-tow connector cap for the Ford Super Duty trucks using Digital Light Synthesis™ (DLS) technology. Additionally, Aptiv’s additive manufacturing strategy provided a tool-free approach, speeding time-to-market by 20 weeks compared to traditional molding solutions.

Fast Radius and Carbon enabled us to additively manufacture Ford’s trailer-tow connector cap, greatly improving our time to market over traditional injection molding and paving the way for future innovations in our lower-volume part production.

MAKING IT POSSIBLE

Trusted materials, leading technology, and additive expertise

1. Trusted materials for automotive applications

This project was Aptiv’s first automotive production application to leverage additive polymer technology. The Carbon team worked closely with Aptiv to choose the right material to meet the product’s USCAR and level 3 sealing requirements. After careful evaluation, Carbon EPX 82 was chosen as the material of best-fit to produce the trailer-tow connector cap.

2. Industrial-grade digital manufacturing technology

Carbon DLS technology met Aptiv’s expectations for speedy, reliable, and scalable production. This made Carbon DLS the right method for the project based on the estimated production volume and scale. Once the technology and materials were locked, Aptiv turned its focus to the connector cap’s design, collaborating with Fast Radius and Carbon engineers to optimize for manufacturing.

3. Production optimization and expertise

Printing thousands of parts repeatedly and reliably at scale with additive manufacturing can be a challenge. Fast Radius infused their intricate knowledge of Carbon’s technology to ensure production reliability. They drew on this experience and the insights gained from their proprietary digital thread software to design a build file that optimally positioned the parts on the build plate to account for subtle variances in temperature and light variation.

4. Quality management system for additive production

Aptiv conducted an extensive on-site audit process of Fast Radius. This resulted in Fast Radius becoming the first serial-approved external additive manufacturing supplier for Aptiv in the automotive industry. Fast Radius relied on its additive manufacturing expertise and software-backed digital thread capabilities to conduct and pass a Production Part Approval Process (PPAP). For production with Carbon DLS technology, Fast Radius instituted part-specific standard operating procedures across each step of the process and developed a rigorous control plan to ensure ongoing quality.

THE RESULTS

The collaboration of Carbon and Fast Radius made Aptiv’s innovative solution for Ford possible.

Stored

In the Fast Radius Virtual Warehouse

Reduced

Time to market by 20 weeks

Streamlined

Additive manufacturing of Ford's trailer-tow connector cap

Gallery

Back

Back