Complex Parts for Challenging Applications

Precision molded parts using a range of materials, tolerances and finishes

Scalability for comprehensive molding needs

Application-specific molding techniques

Material coverage from thermoplastics to additives and fibers

Rapid T-1 samples and post-approval parts

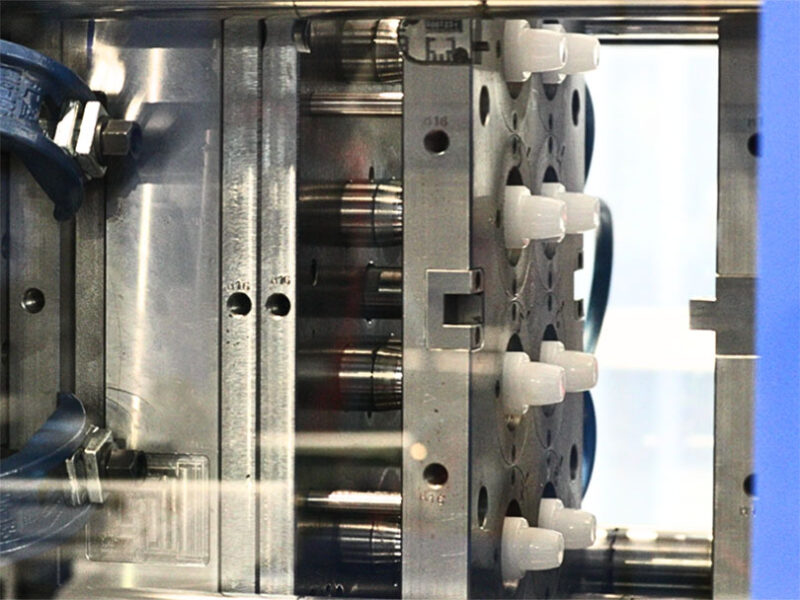

Injection Molding Processes

Plastic Injection Molding

Plastic injection molding is a versatile manufacturing process that utilizes high-pressure injection of molten plastic into a mold cavity to produce a wide range of complex and durable plastic products. This is an ideal process for producing large volumes of standardized parts with excellent mechanical properties.

Insert Molding

Insert molding involves the injection of molten thermoplastic around a pre-placed insert to create strong, durable parts. This technique offers advantages like reduced assembly time, improved product reliability and the ability to combine multiple materials in a single part.

Overmolding

Overmolding is a process in which multiple shots of thermoplastic are injected over or around a substrate to create highly customizable parts. This technique offers versatility and customization options, allowing for the creation of complex and multi-material products with enhanced performance and visual appeal.

Micro Molding

Micro molding is a specialized variation of the injection molding process used to produce small parts with complex geometries. This process allows for the creation of extremely small shot weights, making it a popular option for medical devices, electronics and automotive applications. Micro molding can produce components as small as 0.00025 cc with high quality and repeatability and is compatible with a variety of materials such as PEEK, ABS, Pebax and polypropylene.

Extensive Material Options and Industry-Best Lead Times

Choose from a wide range of thermoplastics with unique properties to achieve the perfect injection molded parts for your application.

| Technology | Materials | Lead Time |

|---|---|---|

| Injection Molding | Most Common: ABS, PC, PE, PP Other Supported Materials: HDPE, LDPE, Nylon (PA 6, PA 11, PA 12, PA 66), PC/ABS, PEEK, PEI, PET, PMMA/Acrylic, POM (Acetal/Delrin), PS, PSU, PU, TPE, TPU, TPV Additives and Fibers: Colorants, flame retardants, glass fibers, plasticizers, UV absorbers | T1 Samples: As little as two weeks Post-T1 Approval: As little as one week for orders of <10,000 parts |

Injection Molding Guidebook