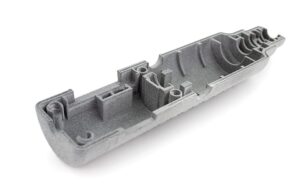

Most are well-acquainted with additive manufacturing (AM) — as a rapid prototyping tool, at least. And while many companies believe and perpetuate the myth that AM is only a prototyping tool, innovators in a range of markets (e.g., aerospace, healthcare, consumer goods and more) are already using AM for production-grade manufacturing when design, performance and cost factors align.

Exploring AM as a means of production opens up design and performance possibilities simply not possible with CNC machining, urethane casting or injection molding. This article will cover how organizations can:

- Identify if there’s a strong business case for switching to AM for your part or product.

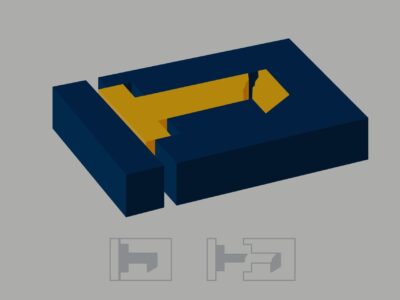

- Leverage design for additive manufacturing (DFAM) principles for a seamless transition from rapid prototyping to rapid production.

Building a Business Case for Adopting Production-Grade Additive Manufacturing

Generally speaking, switching to production-grade AM for a part or product makes sense if there’s potential for adding value through:

- Lightweighting Your Product

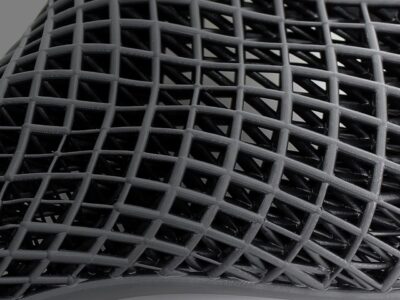

Lightweighting products using AM advances material usage and performance — and opens up opportunity to capture savings throughout the product’s lifecycle. AM has enabled the weight reduction of aerospace parts by as much as 70 percent, saving about $3,000 per year in fuel. - Low-Cost Mass Customization

Consumer demand for customization is rising, with 30 percent of Americans interested in product personalization. And additive manufacturing uniquely allows product designers to meet this demand with lower customization costs and lead times than legacy production methods.Once the base component of your product has been validated with AM, personalizing the product with a corporate logo or different texture is a simple change in the CAD file — with no custom tooling required. Allowing consumers to tailor a product to their design preferences or needs not only helps you stand out among the competition, but it also ultimately provides more value to the customer. - Enhancing Your Product’s Performance

Virtually any shape, feature or function can be produced using AM. And product designers can experiment with vastly different geometries and textures with each design iteration without incurring retooling costs — which can range from $25,000 to $100,000. - Supply Chain Efficiency

It’s estimated that companies leveraging on-demand additive manufacturing can achieve total supply chain savings as high as 50 to 90 percent. Especially for companies selling large quantities of replacement parts, on-demand additive manufacturing opens up opportunity to eliminate warehousing costs and reduce the risk of part obsolescence. - Faster Product Iteration

AM allows design teams to refine and optimize their product with each design iteration. And because you’re prototyping on the same machine your product will be produced on, you can begin to validate the manufacturing process and your product’s performance during the prototype stage. In some instances, the time it takes to go from initial product concept to final product design can be reduced by up to 90 percent.

There are many benefits to making the switch to AM, but of course there are challenges to consider. Producing a part through AM may mean you’re paying a higher per-part cost than conventional manufacturing. However, those fees can be offset because AM also virtually eliminates the need for warehousing, which is critical because housing inventory can add anywhere from 20 to 25 percent to overall costs of production. Contact us today to learn more.