Frequently

asked questions

Categories

General

What is the advantage of working with Fast Radius versus another manufacturing company?

Fast Radius is a manufacturing innovation company. From design to fulfillment, and from prototyping to production, we work collaboratively with our customers as true partners to help make new things possible.

Our partnership model is based on three core pillars: the right people, the right technology, and the right processes.

We drive manufacturing innovation by pairing our engineering, program management, logistics, and design experts with powerful software and a physical manufacturing infrastructure that incorporates both traditional and cutting-edge techniques. We’ve worked hard to develop robust multi-process, on-demand manufacturing programs that enable scalable production at unmatched quality, ensuring that we meet the needs of every customer — without exception.

Rather than settling for the status quo, we’re committed to creating new possibilities through creative partnerships.

What types of parts does Fast Radius make?

We specialize in manufacturing industrial-grade metal and plastic parts for a range of applications, from robotics to motorcycles.

We also offer product development and design services. Get in touch with us to learn more.

What industries does Fast Radius work with?

We work primarily with customers in the consumer goods, medical devices, automotive, aerospace, industrial equipment and electronics industries, but no job is too big or too niche for us. We pride ourselves on being able to provide unlimited manufacturing capacity and quick turnarounds on part production for customers across industries and needs.

Does Fast Radius hold any quality certifications?

We hold dual certifications in AS9100D:2016 and ISO9001:2015.

Processes

What kinds of manufacturing does Fast Radius offer?

We are proud to provide a range of services to help companies leverage the unique advantages afforded by additive manufacturing processes.

In addition to additive manufacturing, we offer a number of conventional manufacturing services, including injection molding, CNC machining, and cast urethane.

Can Fast Radius help me with multiple manufacturing processes?

Yes, we can. Whether your parts require additive manufacturing processes, conventional processes — or both — we’ll help guide you through the entire process, from design and prototyping to production and fulfillment. It’s our goal to help you make every part the right way, using the right processes for your needs.

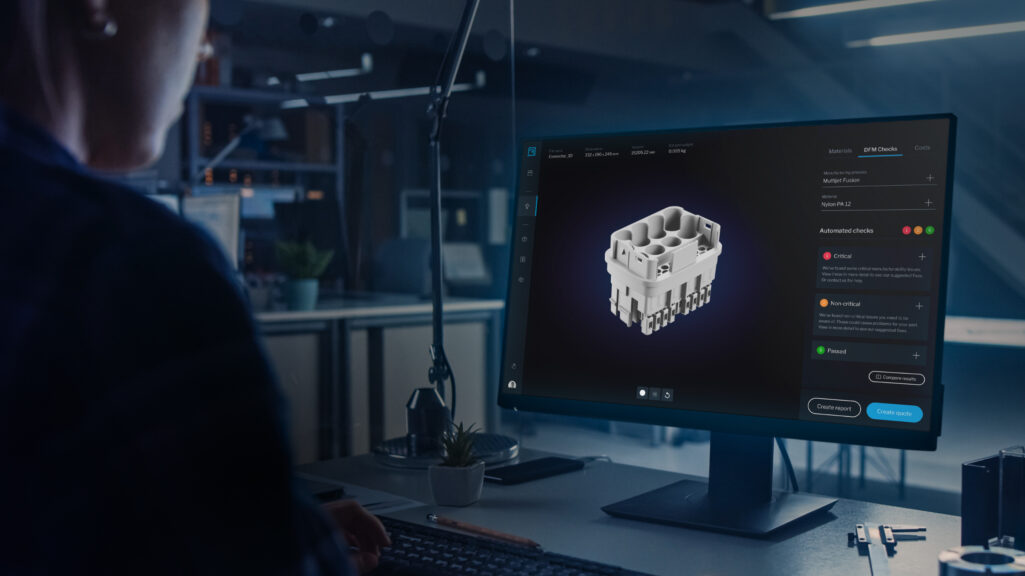

What technology does Fast Radius have in-house?

Named one of the most innovative factories in the world by the World Economic Forum, our additive facility in Chicago’s West Loop neighborhood is designed to ensure unparalleled efficiency throughout the production process.

Our headquarters is home to the largest public install base of Carbon® DLS 3D printers in North America. We also have a large footprint of HP Multi Jet Fusion (MJF) equipment and have a robust presence of Stratasys FDM printers co-located at the UPS World Port facility in Louisville, KY.

We’re committed to ensuring that every customer receives their parts and products as quickly as possible, which is why we’ve also dedicated a large portion of our facility to logistics, packaging, and shipping. Further, we use a state-of-the-art Virtual Warehouse™ to safely store digital designs and product specifications. In doing so, we optimize inventory management and save on storage costs.

In addition to our in-house additive manufacturing solutions, we work closely with vetted global partners to provide other technologies and processes.

Services

Can you help me design my part?

Our team of engineers can help optimize existing designs across manufacturing processes.

We also provide deeper design engagements and consultative services to help bring a part to life from the ground up. Contact us to learn more.

Can you help me convert a 3D design file?

Yes. We have a team of engineers who can help with design files of all kinds. If you need help with your 3D files before you request a quote, please contact our sales or design team directly.

Does Fast Radius offer finishing services? What kinds?

We offer a number of post-processing services, including surface finishes, color options, and chrome plating. Download our line card to see all the finishing and post-processing options we offer.

Do you help with assembly?

Fast Radius is able to support light assembly, such as heat staked inserts and press-fit inserts. Other assembly needs are evaluated on a case-by-case basis.

Ordering and fulfillment

How can I order from Fast Radius?

You can quickly place orders for certain types of projects by uploading your design to our secure interface and following the prompts. If you have questions about ordering or want to consult with one of our experts, you can contact us.

How are prices calculated?

Prices are based on a number of considerations, such as geometry of the part, manufacturing process, material, and order volume.

What if I need to change my order?

If you have an order in progress that you need to change, contact us immediately.

How quickly will my order arrive?

Lead times vary based on process, quality requirements, and order size. Many parts can be produced in 5 business days. You can view process lead times on our line card.

How do I reorder?

If you have been working with an account executive, the easiest way to place a reorder is to call or email them. You may also visit our portal and place an order online.

What is the minimum order quantity?

Fast Radius only has a minimum order size for injection molding projects, which is 100 parts and $5,000. Additionally, there is a set-up fee of $500 per mold per run.

Does Fast Radius have a return or remake policy?

If you are not satisfied with your order, please contact us and let us know what went wrong. Your account executive will work with you on next steps.

Where are my parts made?

Fast Radius has manufacturing capabilities in the United States, Latin America, China, and East Asia. Manufacturing location is dependent on process and project requirements. Our factory in the United States is recognized by the World Economic Forum (WEF) as one of the most innovative factories in the world. If our in-house capabilities can’t fulfill your project requirements, we leverage a highly curated set of independent production partners to meet your manufacturing needs.

If my parts are made overseas, do I have to pay import taxes?

It depends. Currently, there are no duties and taxes for shipments with a commercial invoice value below ~$800 USD. Duties and taxes are subject to change and are dictated by the government. Rates are typically based off of the end-use application of the product as well as material.

How will my order be shipped?

We are able to ship your product using a variety of service levels or methods (e.g., ground) depending on the size of the order and lead time. Please specify your preferred shipping method with your account executive.

Can I choose my own logistics provider?

Yes, you are able to choose your own logistics provider if we ship products using your account. In order to do so, please provide your account executive with the following information: shipping provider (e.g., UPS, FedEx, etc.), shipping service level / method (next day air, ground, etc.), account number, account holder’s zip code.

Additive manufacturing

What is additive manufacturing?

Additive manufacturing, commonly called industrial-grade 3D printing, refers to the family of processes that allow us to construct geometrically complex parts by quickly adding material a layer at a time.

What’s the difference between additive manufacturing and 3D printing?

Both terms tend to be used interchangeably in reference to the process of layer-based manufacturing, which may involve a variety of materials. However, “3D printing” refers specifically to the process of creating an object layer-by-layer, whereas “additive manufacturing” describes, more generally, the group of industrial-grade processes involved in creating the final product. This may involve everything from designing and prototyping to manufacturing and supply chain solutions.

When should I consider additive manufacturing?

Additive processes build parts a layer at a time, enabling the production of complex parts in a single operation. As such, additive manufacturing is ideal for prototyping, producing mass customized parts, executing on low-volume production runs, consolidating parts, and creating parts with complex geometries that couldn’t be made any other way.

What’s more, additive manufacturing enables a greater degree of customization and manufacturing on demand. Additive methods don’t require the tooling associated with traditional manufacturing. This accelerates overall production speed, making it possible to build, test, and modify prototypes with increased efficacy.

By storing digital part designs in the Fast Radius Virtual Warehouse™, we’re also able to print parts on demand without the associated costs of tooling, storing components, or disposing of material waste. Traditional manufacturing methods often require high minimum order quantities to be economically viable, but this isn’t the case for additive manufacturing, which allows us to produce the exact number of parts that our customers need at a given time. As a result, we mitigate volumes of material waste, unused or obsolete parts, and carbon emissions.

What’s the best additive material for my part?

A wide range of materials can be used in additive manufacturing, and the type of product or process best suited for your order will ultimately determine which materials are used. Many additive materials can easily replace common injection molding plastics without sacrificing performance.

Get in touch with one of our experts for a professional materials assessment and check out our Guide to Additive Polymers to learn more.

I want to make an existing part with additive manufacturing What should I do?

We specialize in reverse engineering services for legacy parts, determining how to construct existing parts more efficiently with additive manufacturing. We compiled our experience in additive conversion into a guide; download it to see how you can begin producing existing parts additively. If you’re ready to get started, get in touch and one of our experts will be happy to help.

What kinds of 3D printing technology do you offer?

Our in-house technologies include Carbon Digital Light Synthesis (DLS), HP Multi-Jet Fusion (MJF), and Stratasys Fused Deposition Modeling (FDM). In addition to our in-house capabilities, our global network allows us to facilitate Stereolitography (SLA). More details on our process offerings can be found here.

How do I design a part for additive manufacturing?

There are a few key factors to keep in mind when designing parts for additive manufacturing.

Complex parts are easier to make on more complex machines, but these are often more expensive to purchase and operate. By isolating the geometrically complex features that would be more difficult to manufacture using traditional manufacturing methods, you are able to simplify and streamline your designs.

Different processes come with different benefits and constraints as well. Some technologies require parts be designed with support structures, some need to account for powder removal — make sure you’re familiar with your chosen technology before you begin production.

You’ll also need to consider not only how printable the part is, but how it will meet the functional and performance requirements of the finished product. The best-designed parts are those that take full advantage of the machines and processes available to them in order to achieve greater quality and efficiency. If you have questions, don’t hesitate to contact us. We’re here to help.

Can I use additive manufacturing for production parts?

Yes! Advances in additive manufacturing processes and materials mean that a number of industries — including aerospace, medical, automotive, and more — are turning to 3D printing for optimized part production. We’ve worked with a variety of companies across many industries to produce production-grade additive parts. You can see their stories on our website.

What file type do you need to 3D print my part?

Our preferred file format is STEP, uploaded as a ZIP file. You can request a quote or contact our team for more information.

What is HP Multi-Jet Fusion? What are its advantages?

HP Multi-Jet Fusion (MJF) is an incredibly efficient 3D printing process that leverages fusing and detailing agents and infrared lamps to build complex or intricate parts 80 microns at a time. As such, the process lends itself to superior detail and dimensional accuracy in the manufacturing of parts.

MJF enables printing times up to 10 times faster than traditional manufacturing processes, and in some cases is more cost-effective than injection molded parts. Read more about the specifications of the process here.

What is Carbon Digital Light Synthesis (DLS)? What are its advantages?

A process created by Carbon™, Digital Light Synthesis™ (DLS) uses a combination of UV light projection and tunable liquid resins to create parts with exceptional resolution and surface finish. DLS yields consistent and predictable isotropic mechanical properties, like those produced through injection molding. The DLS process can be used with a wide variety of production-grade materials. Find out more about this unique process here.

What is Fused Deposition Modeling (FDM)? What are its advantages?

Fused Deposition Modeling (FDM), or fused filament fabrication (FFF), refers to the process of using a heated nozzle to melt and extrude thermoplastic material a layer at a time along a toolpath. The primary benefits of FDM are that it has short lead times and is an extremely cost-effective way of producing everything from design prototypes to finished products. Learn more about this flexible and adaptable process here.

What is SLA?

Stereolithography (SLA) is the process of creating parts by firing a laser into a pool of UV-curable resin to selectively solidify each layer. These lasers can be finely tuned, resulting in exceptional surface finish. SLA is one of the best options for creating high-resolution parts that have a set lifetime and mechanical load. For more information, click here.

What is material extrusion?

Material extrusion refers to the process of using a heated nozzle to melt and place layers of raw material along a toolpath. Fused Deposition Modeling (FDM) is one example of this kind of process.

What materials are available for additive manufacturing?

A full list of materials that can be used with each process we offer is available here.

What finishing services do you offer for additive manufacturing?

We offer comprehensive finishing and post-processing for all of our additive manufacturing processes. Download our line card for more information.

Where can I learn more about additive manufacturing?

Check out our resources library to learn more about different manufacturing processes and materials.

Conventional manufacturing

Does Fast Radius offer injection molding?

Yes. Find out more about our injection molding services here.

What are the mechanical specifications I can expect from injection molding?

Mechanical specifications, lead times, minimum order quantities, set-up fees, materials and finishing options for injection molded parts can be found on our line card, which you can download here.

When should I use injection molding over additive manufacturing?

Injection molding is a better choice for creating high-volume production runs of repeatable parts. The injection molding process offers high production speeds and results in consistent and highly refined part quality, low scrap rates, and lower price-per-part. High volume, consumer-facing parts can benefit from this process, including items like bottle caps and toys. You can find out more about injection molding here.

Does Fast Radius offer CNC machining? What types?

In addition to 3D printing, we’re proud to offer a number of traditional manufacturing methods, including CNC machining. We use lathe-, router-, mill-, and drill-based CNC machining equipment. Learn more about our CNC machining services here.

What are the mechanical specifications I can expect from CNC machining?

Mechanical specifications, lead times, minimum order quantities, set-up fees, materials and finishing options for CNC parts can be found on our line card, which you can download here.

Does Fast Radius offer cast urethane?

Yes. You can learn more about our cast urethane offerings here.

When should I use cast urethane vs. injection molding?

Cast urethane parts can be created quickly and affordably, but they are less durable than injection molded parts. Urethane casting is typically a better choice for prototypes and small-volume production because it doesn’t come with the expensive upfront costs of injection molding. Conversely, injection molding is a more cost effective choice for high volume runs, and it’s capable of producing more durable parts with tight tolerances. You can read more about the differences between the processes here.

What if I want to use a process that’s not on your site?

Contact us! The roster of services and capabilities we offer continues to expand rapidly, so if you don’t see the specific process or material you’re looking for, don’t hesitate to get in touch.

Working with Fast Radius

Where is your office located?

Our headquarters is located in Chicago, and we have a factory co-located with the UPS global distribution facility in Louisville, KY. We also have offices in Atlanta, GA, and Singapore.

How can I contact Fast Radius?

Our contact page is the easiest way to reach us. We’ll get in touch as soon as possible.

What’s the story behind Fast Radius?

Fast Radius is a venture-backed company that opened in 2015 with aspirations to build industrial-grade components for airplanes, medical applications, and cars using additive manufacturing. In 2018, we moved to our state-of-the-art headquarters in Chicago’s West Loop, where we’ve been working to create a disruptive and innovative production model that uses the latest developments in additive and traditional manufacturing technologies.

What is the WEF Lighthouse Global Network?

World Economic Forum’s Global Lighthouse Network is a community of leaders that are leveraging emerging technology to address the most pressing issues facing our world today. Currently, the WEF recognizes 44 “lighthouses” across a range of industry sectors. We’re thrilled to have been named one of the first nine manufacturing lighthouse companies in the world by WEF in 2018.

What is the relationship between Fast Radius and UPS?

UPS is among our largest investors. We work closely with UPS’s global distribution center in Louisville, KY, augmenting our fast production times with a guarantee of speedy shipping and delivery.

Are you hiring?

Interested in joining our team? All of our open career opportunities can be found here.

Back

Back