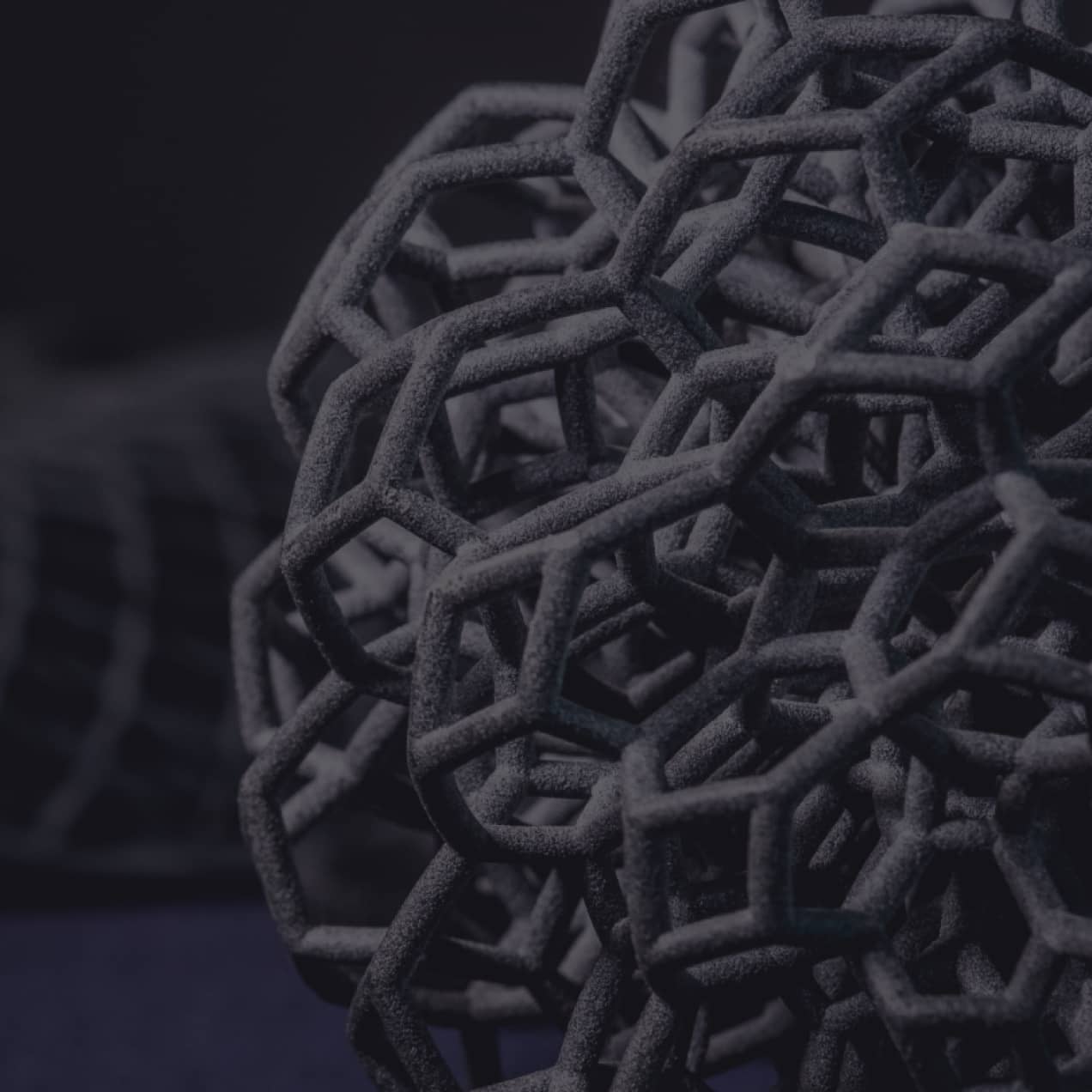

HP Multi Jet Fusion (MJF) 3D printing service

HP MJF 3D printing is a powder bed fusion process that creates strong parts with high dimensional accuracy. Because MJF doesn’t require support structures, the process allows more design freedom than many other 3D printing processes.

Fast Radius is a member of HP’s Digital Manufacturing Network, meaning our production facility meets HP’s highest standards for quality. Our factory houses three HP Jet Fusion technologies: 4200/5200 3D Printing Solutions, which are known for creating durable parts that meet many regulatory requirements; and the HP Jet Fusion 580, which uses the same technology to print parts in full color.

Producing parts with HP MJF

| Build volume | 375 x 375 x 280 mm 14.8 x 14.8 x 11.0 in |

| Minimum feature size | 0.5 mm 0.02 in |

| Lead time | As low as 4 business days for Nylon PA 12 As low as 5 business days for 40% Glass Bead Filled Nylon PA 12 As low as 5 business days for TPA |

| Maximum part size | 332 x 190 x 248 mm 13.1 x 7.5 x 9.8 in |

| Minimum feature size | 0.5 mm 0.02 in |

| Lead time | As low as 5 business days |

| Nylon PA 12 | 40% Glass Bead Filled Nylon PA 12 | TPA |

| Painting | Bead blasting | Press-fit inserts | Clear coat |

| Black dyeing | Heat staked inserts | Digital texturing |

| CB Nylon PA 12 – accepts all CMYK values |

| Painting | Bead blasting | Heat staked inserts | Press-fit inserts |

| Digital texturing | Clear coat |

Let’s make your HP MJF parts.

Right now.

Made possible with

Fast radius

Every day we’re working with the world’s leading product manufacturers to make the parts that matter most to their businesses.

Common HP MJF applications

MJF parts have high tensile strength and sufficient resolution for many end-use applications.

Complex assemblies

Consolidate several parts into one.

Functional prototyping

Durable prototypes suitable for testing in real-world conditions.

Chemical-resistant parts

Resistance to oils, greases, aliphatic hydrocarbons, and alkalies.

Housings, fixtures, tooling, connectors

Ideal for applications requiring high stiffness.

Fast Radius manufacturing solutions

Fast Radius manufacturing solutions, including 3D printing, are used by businesses across the world. Learn more about our manufacturing capabilities:

3D printing

Fast, scalable, and cost-effective 3D printing technology for a variety of industrial applications.

CNC machining

Precision computer-controlled machining processes, utilizing rotating drills, end mills, and lathes.

Back

Back