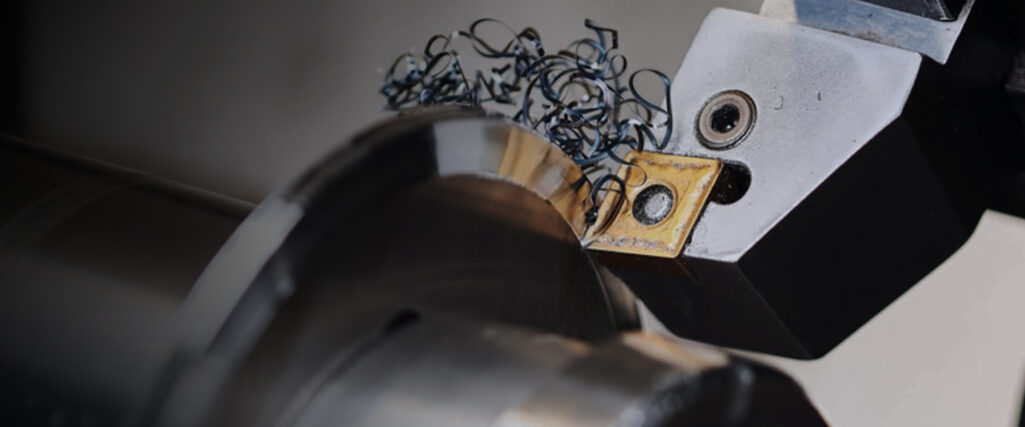

CNC turning services

Machine parts with computer-controlled efficiency and precision, and scale easily for high volume production.

What is CNC turning?

CNC turning involves the application of a cutting lathe to a rotating blank workpiece in order to shape a desired part. During production, the workpiece spins on vertical or horizontal axes, while the automated lathe moves around it. Precise, repeatable, and scalable, CNC turning is ideal for creating parts with simple geometries and rounded or cylindrical shapes, as part of high volume production runs.

Begin your CNC turning project by uploading your CAD file to our Cloud Manufacturing Platform™. We’ll work with you to optimize your design and choose your material, and then take your project to production quickly and efficiently.

For more on-demand manufacturing options, browse our CNC machining capabilities, including our CNC milling services.

Design considerations

Fast Radius machining capabilities deliver precision parts quickly. Optimize your CNC turning project with the following design considerations, production materials, and finishing and post processing options:

| Maximum part size | Ø 350 x 600 mm Ø 13.8 x 23.6 in Larger diameters may be feasible at shorter lengths. Contact us to discuss design options. |

| Minimum part size | 6.4 x 6.4 x 6.4 mm 0.25 x 0.25 x 0.25 in |

| Minimum feature size | • Ø 1 mm • Ø 0.039 in |

| Standard tolerance | Metals: +/-0.13 mm (0.005 in) Plastics: +/-0.20 mm (0.008 in) |

| Minimum wall thickness | Recommended size: 0.8 mm (0.031 in) for metals and 1.5 mm (0.059 in) for plastics Feasible size: 0.5 mm (0.019 in) for metals and 1.0 mm (0.039 in) for plastics |

| Holes | Recommended size: Diameter: standard drill bit sizes Depth: 4 x diameter Feasible size: Diameter: Ø 0.5 mm (0.019 in) Depth: 8 x diameter |

| Threads | Recommended size: Size: M6 or larger Length: 3 x diameter Feasible size: Size: M2.5 |

| Lead time | As low as 8 days for less than 50 parts |

| Plastic | Aluminum | Stainless Steel | Other Steel | Other Metal |

|---|---|---|---|---|

| ABS | 2024 | 303 | Mild steel | Brass |

| Nylon 6 | 6061 | 304 | Alloy steel | Copper |

| Acetal (Delrin) | 6082 | 316 | Tool steel | Titanium |

| Polycarbonate | 7050 | 17-4 | Contact us for additional metal machining options | |

| PVC | 7075 | 420 | ||

| HDPE | ||||

| PTFE (Teflon) | ||||

| PEEK | ||||

| Nylon 30%GF | ||||

| UHMW |

| As machined (standard) | Bead blasting | Polishing | Heat treating | Black oxide |

| Anodizing | Brushing | Screen printing | Passivating | |

| Powder coating | Painting | Engraving | Plating |

Get an instant quote for your

CNC turning project

Use our quoting platform for quick quotes on production parts and prototypes.

Why choose CNC turning?

CNC turning offers flexibility, precision, and cost-effective speed. Explore some of the key benefits and challenges of the process here:

Benefits

Benefits

- Excellent design precision

- Cost-effective speed and capacity

- Production consistency

- Suitability for niche products

- Established technology

- Wide variety of materials

- Scalability

Challenges

Challenges

- Upfront design costs

- Potential unused material waste

- Less suited to non-axisymmetric parts

CNC turning applications

From single parts to full production runs, key applications of CNC turning include:

Tooling

Manufacture parts with complicated cuts and different angles using a variety of cutting, drilling, and lathing tools.

Metal fabrication

CNC turning is a safe, effective way of creating high quality metal parts with exceptional tolerance levels.

Niche manufacturing

CNC turning is capable of creating a range of niche, durable metal or plastic products that alternative manufacturing processes cannot.

Hybrid manufacturing

CNC turning is not just a process suited to working with metals: molded and 3D printed parts can also be machined.

Medium-to-high-volume production

The CNC turning process is particularly useful for high-volume manufacturing runs, offering automated speed and cost benefits.

Rapid prototyping

The CNC turning process is fast, automated, and useful for the production of prototype parts.

Fast Radius manufacturing solutions

Fast Radius manufacturing solutions, including CNC turning, serve customers across the world. Learn more about our capabilities:

3D printing

Fast, scalable, and cost-effective 3D printing technology for a variety of industrial applications.

CNC machining

Precision computer-controlled machining processes, utilizing rotating drills, end mills, and lathes.

Back

Back