Injection molding finishing & post-processing

Design injection molded parts with finishing and post-processing options that enhance their functionality and end-use.

What is injection molding finishing and post-processing?

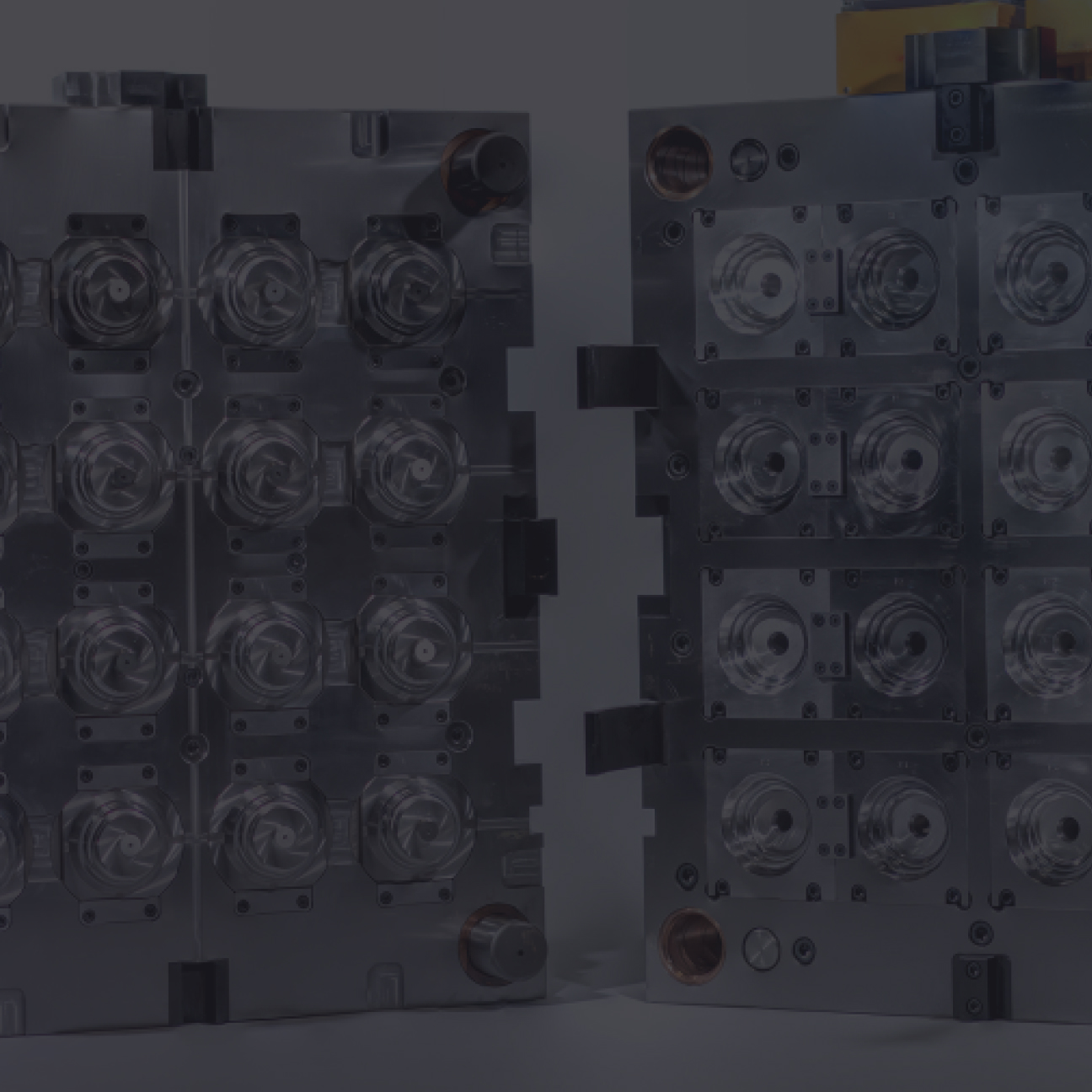

Ideal for high-volume manufacturing requirements, injection molded parts can be customized with a variety of finishing and post-processing options. Whether you need to strengthen your part with inserts, add textures or detailing, or apply painted colors or graphics, we’ll help you select the finishing process that suits your project’s needs.

Begin your injection molding manufacturing project today: upload your CAD file to our Cloud Manufacturing Platform™, work with our engineers to optimize your design, and choose from the range of finishing and post-processing options that we offer. We’ll apply your selection to your order when you greenlight production.

Learn more about our full range of injection molding services, including multi-cavity molding, insert molding and overmolding.

Injection molding finishing and post processing options

Browse our injection molding finishing and post-processing services:

Colors

Pantone color matching

Match and color your injection molded parts to the standardized Pantone Color System.

RAL color matching

Use the European RAL color matching system to add standardized color to your injection molded parts.

Finishing and post-processing

SPI standard

Add standard SPI finishes (D3 to A2) to the surface of your injection molded parts.

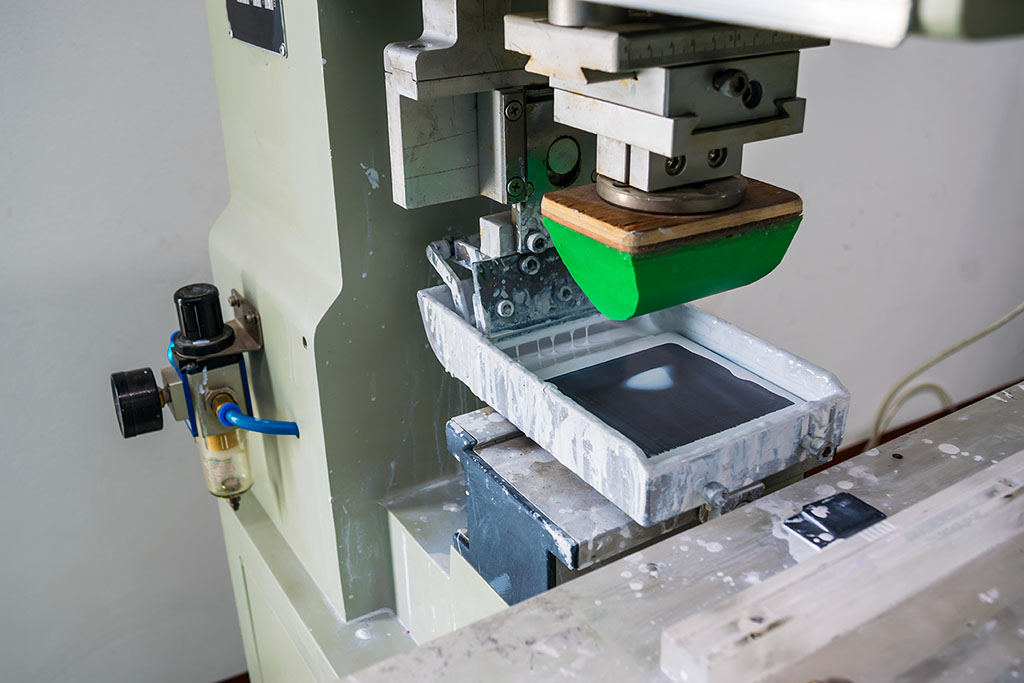

Pad printing

Transfer two dimensional designs to your injection molded parts using pad printings designed for organic curves and features.

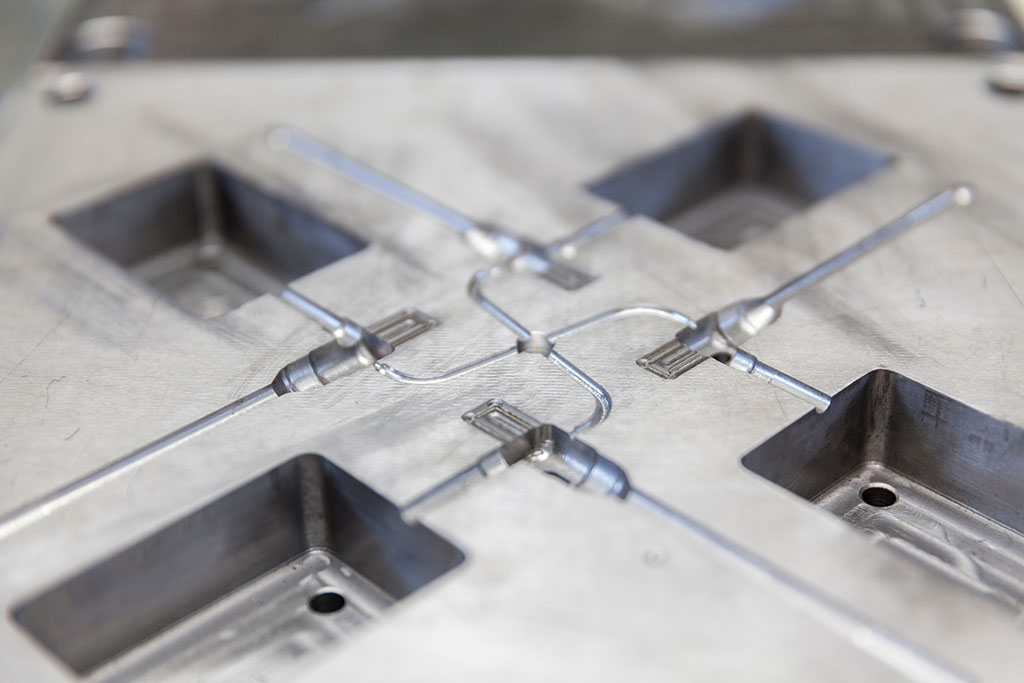

Inserts

Strengthen and augment your injection molded parts by adding preformed (often metal) inserts.

Mold-Tech textures

Apply a range of Mold-Tech textures – from smooth to rough – to your injection molded parts.

Light assembly

Combine injection molded parts with other parts and components with our light assembly service.

Protective packaging

Prepare your injection molded parts for shipping and delivery with protective packaging options.

Why choose Fast Radius for finishing and post-processing?

The factory of the future

The Fast Radius Cloud Manufacturing Platform™ combines digital design technology with the expertise of our team to make your project possible.

Get a quote for your injection molded parts

Create a Fast Radius account for rapid quotes on parts production.

Fast Radius manufacturing capabilities

Fast Radius manufacturing solutions serve the needs of businesses across the industrial landscape. Explore our capabilities:

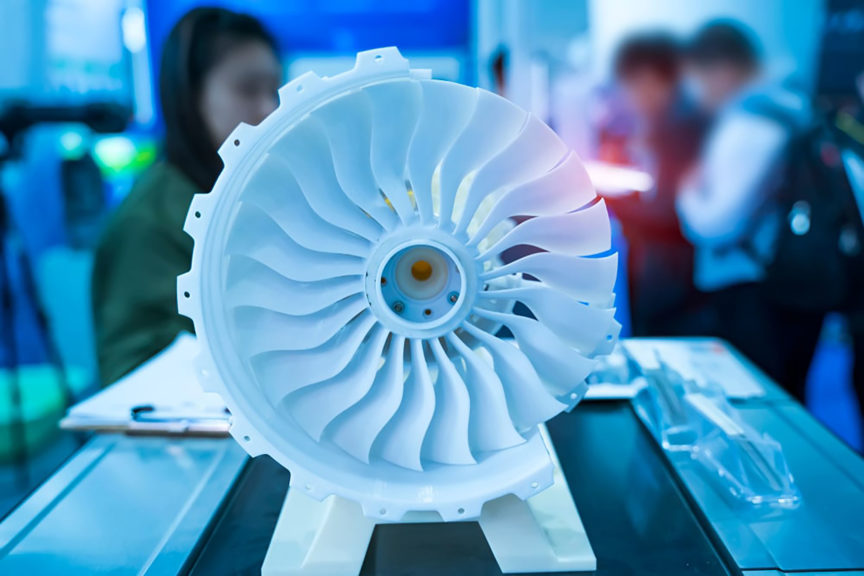

3D printing

Fast, scalable, and cost-effective 3D printing technology for a variety of industrial applications.

CNC machining

Automated CNC turning and 3-axis and 5-axis milling, using rotating drills, end mills, and lathes.

Back

Back