Stereolithography (SLA) 3D printing service

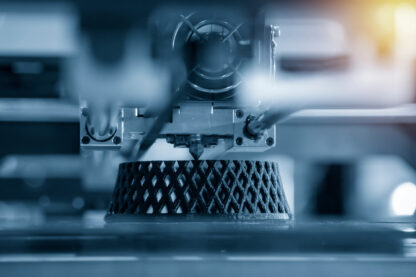

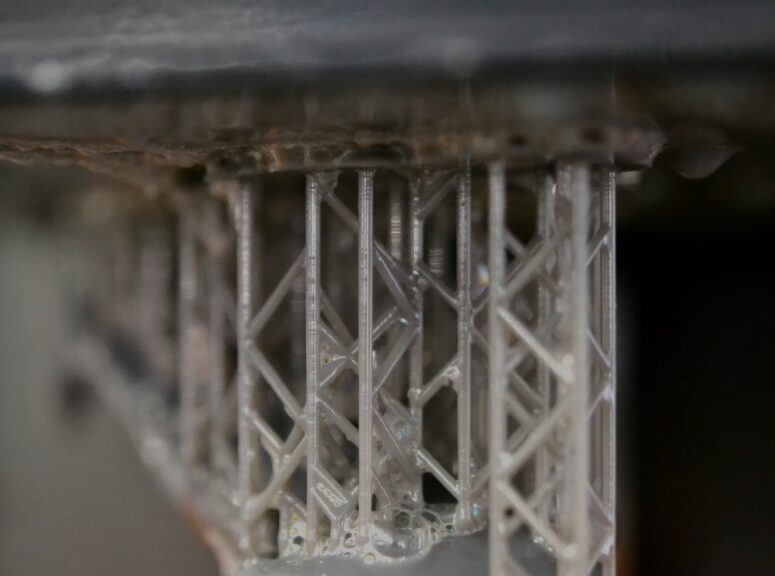

SLA is a type of photopolymerization capable of producing parts with an excellent surface finish and small feature resolution. While SLA is not typically suitable for high-performance applications, its intricate and accurate detailing make it a popular option for prototypes. Our factory uses Formlabs Form 3 SLA 3D printers.

Producing parts with SLA

| Build volume | 335 × 200 × 300 mm 13.2 × 7.9 × 11.8 in |

| Minimum feature size | The minimum feature size is different for each resin, but we are able to achieve complex and aggressive geometry. |

| Lead time | Get your prototypes in as little as seven days. Production or high volume runs will be examined on a case by case basis. |

| Material | Color | Hardness (post-cure) | Description |

|---|---|---|---|

| Surgical guide | Clear orange | 67D | Biocompatible Sterilizable and solvent safe Good material properties |

| Clear | Clear | 82D | Able to make clear parts with intricate features Not optically clear but perfect to let light pass through and achieve some |

| Rigid | White | 89D | Strong, stiff, and resistant to bending Soft matte white finish |

| Tough 2000 | Gray | 81D | Strong and sturdy Good for prototypes Resistant to bending |

| Tough 1500 | Medium Gray | 76D | Resilient rigid resin Good for stiff but pliable parts that spring back into shape |

| Elastic | Clear | 50A | Springy, bendable and stretchable Will return quickly to original shape |

| Flexible | Black | 80-85A | Dampening properties Good for cushioning and soft touch areas Stronger mechanical properties than Elastic |

| Durable | Translucent, Clear | Pliable, impact resistant, lubricious Ideal for high wear areas or rigid parts that need to be pliable | |

| White | White | Matte white Able to achieve precise details Good for general prototypes or aesthetic parts | |

| Black | Black | Matte black Able to achieve precise details. Good for general prototypes or aesthetic parts. | |

| Color | Select colors available | Color resin Able to achieve precise details Good for general prototypes or aesthetic parts Only available for production qty orders | |

| High temp | Translucent Orange | Detailed precise prototypes Able to withstand temperatures up to 238 °C |

| Painting | Bead blasting | Sanding | Press-fit inserts |

| Digital texturing |

Need information on design guidelines, pricing, and lead times?

Made possible with

Fast radius

Every day we’re working with the world’s leading product manufacturers to make the parts that matter most to their businesses.

Common SLA applications

SLA 3D printing produces parts with small feature resolution and excellent surface finish, making it a good technology for applications where details are important.

Master patterns

High dimensional accuracy for precise patterns.

Scale models

Capable of producing intricate details with high-resolution.

Prototypes

Excellent resolution, small feature size, and finish.

Fast Radius manufacturing solutions

Fast Radius manufacturing solutions, including 3D printing, are used by businesses across the world. Learn more about our manufacturing capabilities:

3D printing

Fast, scalable, and cost-effective 3D printing technology for a variety of industrial applications.

CNC machining

Precision computer-controlled machining processes, utilizing rotating drills, end mills, and lathes.

Back

Back