Making industrial drone flight possible

The Challenge

Manufacturing rugged,

autonomous commercial drones with cutting-edge technology

Digital Aerolus went searching for an on-demand manufacturer to make two parts and came away with a long-term strategic partnership for the ongoing production of more than 100 components.

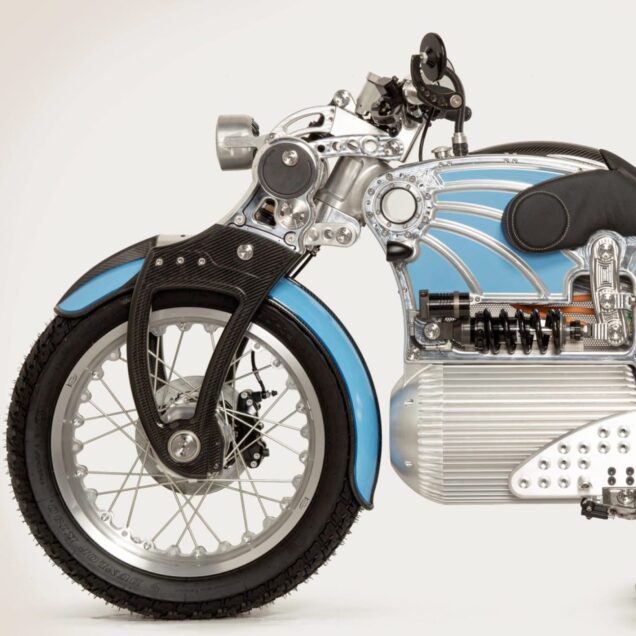

Digital Aerolus first came to Fast Radius needing two 3D printed parts for the Aertos 120, a drone that operates in confined spaces — like inside pipes, nuclear reactors, chimneys, or mines. Fast Radius introduced Digital Aerolus to HP Multi Jet Fusion 3D printing technology and manufactured parts that exceeded Digital Aerolus’ performance expectations while meeting their timeline and budget.

Pleased with their first engagement, Digital Aerolus approached Fast Radius to produce 50 functional prototypes of a ground control unit (GCU) for their new family of autonomous industrial platforms, including the flagship Aertos 130IR. Fast Radius helped Digital Aerolus find the right technology for each part and adjusted designs for manufacturability.

As a multi-process manufacturing partner, Fast Radius also handled production for almost every mechanical component in the GCU, managing manufacturing across cast urethane, CNC machining, the Carbon Digital Light Synthesis™ (Carbon DLS™) process, and HP Multi Jet Fusion in conjunction with a variety of texturing and graphics processes. Also, Fast Radius provides injection molding services since Digital Aerolus has moved the GCU into volume production.

After working together to find innovative solutions for many parts on the Aertos 130IR, the partnership between Fast Radius and Digital Aerolus is expanding to include newer platform models. Fast Radius has become a one-stop shop for Digital Aerolus, helping them optimize parts for multiple processes and scale products from prototyping to production.

Making it possible

On-demand production and a flexible long-term partnership

1. Multi-process manufacturing

To make the prototypes and early production models for the Digital Aerolus GCU, Fast Radius broke down the entire 40-plus part mechanical assembly and suggested the best manufacturing method for each piece. After landing on a combination of cast urethane, DLS, MJF, and CNC machining, Fast Radius managed production and finishing for every part. As the GCU has entered volume production, Fast Radius also provides volume tooling and injection molding support.

2. Design for manufacturing expertise

Fast Radius engineers provided design for manufacturing (DFM) support for the GCU parts across four different processes. Fast Radius adapted those designs for manufacturability with injection molding and helped implement necessary product changes as Digital Aerolus moved from prototyping to early production to volume production.

3. Production-grade additive manufacturing

Digital Aerolus originally planned to make a rotor and duct for their drone using a 3D printing technology often used for prototypes. The Fast Radius team suggested they try HP MJF instead to create longer-lasting, more durable parts. The final parts, made of PA 12 Glass Bead using MJF, are far more robust and resistant to extreme conditions.

4. Cutting edge technology

Digital Aerolus had a unique challenge with the housings on the top and bottom of the drone that needed to be transparent enough to diffuse light without revealing the hardware beneath. Fast Radius suggested LOCTITE 3D IND405, a new material for the Carbon DLS process that hadn’t hit the market yet. With its adjustable level of transparency and custom digital texturing options, LOCTITE 3D IND405 proved perfect for the part. These parts were also some of the first Fast Radius printed on the Carbon L1, a new large-format 3D printer. The large build volume on the L1 allowed Fast Radius to print the part as one single piece, which they wouldn’t have been able to do with a smaller printer.

We make the most advanced drones in the world, with hundreds of computer processing elements and dozens of sensors —all enabled by cutting-edge AI, control systems, and software. Our customers expect extraordinary performance, and we expect the same from our partners.

Gallery

The Results

A partnership helping innovation take flight

117

Parts

made by Fast Radius in the Aertos 130IR drone and GCU

15

Materials

used in the Aertos 130IR

6

Processes

used across Digital Aerolus parts

95%

BOM

made by Fast Radius in the Aertos 130IR drone and GCU

Back

Back