Making superior recovery possible

Flip Rehab had an idea and design for a novel solution to a common physical ailment: the Shin Splint Sandal. As a new business learning the manufacturing process, they came to Fast Radius for help bringing this idea to life and ultimately scaling production.

the challenge

Taking a new physical therapy solution to market

Flip Rehab needed manufacturing experts to create Shin Splint Sandal prototypes and move into production. With Fast Radius, they found a partner to create prototypes, refine designs for manufacturability, and transition their product to injection molding.

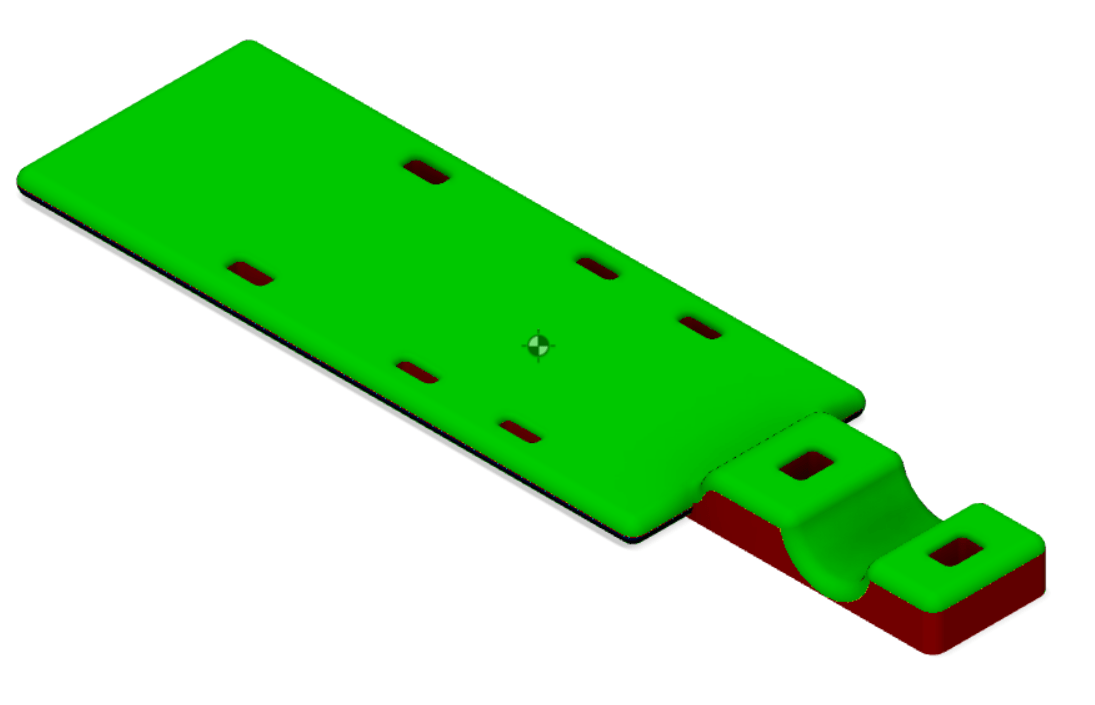

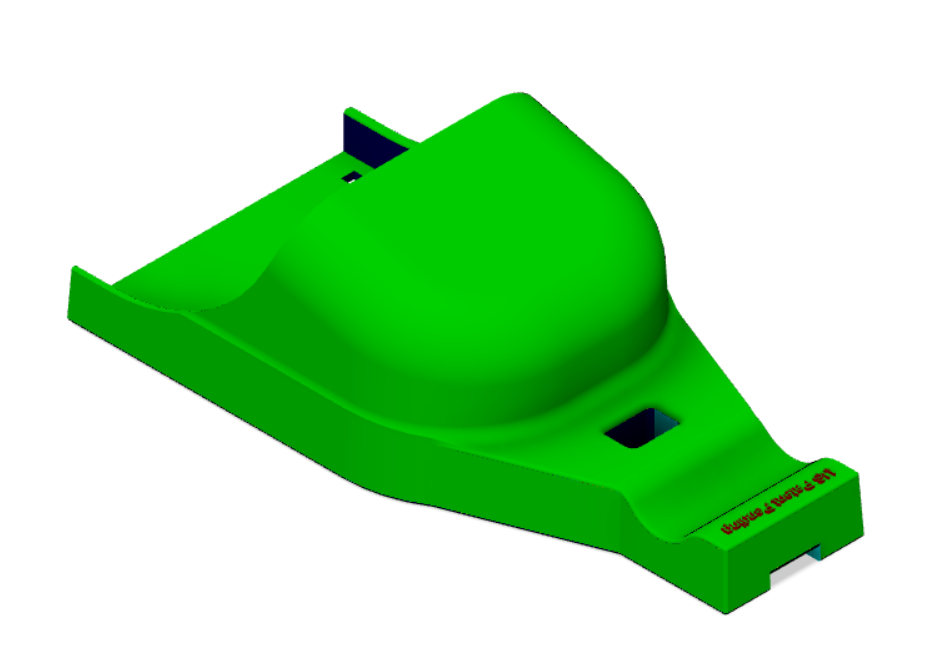

Traditionally, the results from physical therapy for shin splints are equivalent to simply resting the leg muscles. One entrepreneur at Flip Rehab decided to create a solution that could improve results and make a bigger impact. Inspired by swimming flippers, they developed a product that conditions and strengthens the lower leg and shin muscles to improve recovery and reduce the risk of future injury. Thus, the Shin Splint Sandal was created – they developed an initial CAD model; however, making the model into a real product was difficult.

With the CAD model in hand, 3D printing was the natural next step, but there were a few barriers to overcome. First, the designer had no experience with 3D printing and needed an expert to help. Second, the initial prototypes measured 18 inches long – much too large for a hobbyist desktop printer – and needed additional design changes to be manufacturable. Fast Radius was a natural fit to provide design for manufacturing feedback and start printing the prototypes on industrial-grade 3D printers.

Fast Radius’ team optimized designs for manufacturability and began printing small numbers of prototypes with Fused Deposition Modeling (FDM). Through multiple design iterations and quick manufacturing cycles, the Shin Splint Sandal design was finalized, with a U.S. patent pending. Fast Radius’ team then helped adapt the design for injection molding, ensuring it can be mass-produced to the quality and specifications necessary for consumer use.

When you’re trying to create something new, it’s a huge advantage to have a true partner on your side. Fast Radius gave me the options I needed and had the resources to help me manufacture my product from start to finish.

making it possible

A manufacturing partnership from prototype to production

1. Rapid prototyping

Flip Rehab needed the opportunity for real-world testing to improve prototypes before determining a final design. With rapid manufacturing in Fast Radius’ FDM microfactory in the UPS Worldport facility in Louisville, prototypes were quickly produced and shipped to meet tight turnaround needs.

2. Ongoing design support

As a small startup, Flip Rehab needed external help refining FDM prototype designs for manufacturability. Fast Radius’ Customer Application Engineers provided hands-on support for each design iteration to ensure the prototypes would fit manufacturing standards and functional requirements.

3. Scaling to injection molding

To transition from individual prototypes to injection molding, Fast Radius’ team helped address common injection molding design challenges like wall thickness. The final parts, injection-molded with Nylon 12, are much stronger than original prototypes and can be manufactured in larger volumes without visual or structural flaws.

4. Transparent partnership

Developing and scaling a new product can be a massive challenge, especially when navigating the manufacturing industry for the first time. Fast Radius provided Flip Rehab with the insight needed into the process and costs of manufacturing, offering a variety of different manufacturing processes and cost breakdowns to help them make the best decision for their business.

Gallery

the results

Manufacturing support to refine and scale a new recovery tool

<1 week

turnaround time on average for prototypes

10

FDM prototypes before final designs

500

parts made in first injection molding run

67%

less material used in the final product

Ready to make your parts with Fast Radius?

Making beautiful music possible

ClarinetXpress needed to find a way to make high-performing clarinet mouthpieces for elite musicians after they lost a trusted supplier. Fast Radius helped them leverage the unique benefits of additive manufacturing to find a long-term production solution.

THE CHALLENGE

Improving design, manufacturing, and fulfillment with additive manufacturing

After losing their longtime CNC supplier, ClarinetXpress struggled to find a partner who could meet their expectations for quality and turnaround time.

World-renowned clarinet technician and authority Walter Grabner founded ClarinetXpress more than 20 years ago to bring professional-grade clarinet mouthpieces to musicians around the world. His mouthpieces have made music in venues like Carnegie Hall and the Sydney Opera House. For years, ClarinetXpress products were made by a skilled machinist in Germany. When this manufacturing partner decided to retire, ClarinetXpress needed to quickly find another way to make their mouthpieces.

They tried other CNC machining providers first, but they took too long to deliver prototypes and none could produce the quality needed. That’s when ClarinetXpress decided to try additive manufacturing.

Their first attempt at 3D printing didn’t produce acceptable results, so they turned to Fast Radius. By taking advantage of Fast Radius’s design expertise and the unique benefits of additive manufacturing, ClarinetXpress improved its design, manufacturing, and fulfillment processes.

The capacity to produce prototypes quickly is invaluable to me. Being able to make quick changes and alterations to my mouthpieces has allowed me to deliver an exceptional product to my customers.

MAKING IT POSSIBLE

Additive manufacturing breathes new life into musical instrument production

1. Engineering expertise

ClarinetXpress tried other 3D printing companies, but the resulting mouthpieces did not look or feel smooth enough. Determined to find a better solution, the application engineers at Fast Radius sat down with Grabner to understand his performance and aesthetic requirements. They determined that Rigid Polyurethane (RPU 70) printed on Carbon® Digital Light Synthesis™ (DLS™) technology would give the mouthpieces the right look, feel, and sound.

2. Rapid prototyping

ClarinetXpress and Fast Radius went through several rounds of rapid prototyping within a few weeks. Making a single prototype with their former supplier would have taken at least a month. At each step in the process, the Fast Radius team helped ClarinetXpress optimize their designs for Carbon technology. Now that ClarinetXpress is more familiar with designing for additive manufacturing, they can prototype even faster.

3. Reliability and repeatability

Even the tiniest variation in a mouthpiece can alter the sound of a clarinet drastically. Mouthpieces need to meet precise specifications to achieve the quality and pitch demanded by elite musicians. With additive manufacturing, ClarinetXpress produces parts that meet these requirements, down to one hundredth of a millimeter in some cases. This makes more uniform products than ClarinetXpress achieved with CNC because Carbon DLS technology uses the same digital design to make identical parts every time.

4. Customization

ClarinetXpress can customize their products much more easily with additive manufacturing. With CNC, each mouthpiece had to be stamped or hand engraved with their logo after it was fabricated. With additive, ClarinetXpress prints the logo right on the part, eliminating the headache and cost of managing another step in the production process.

5. Low volume production and the virtual warehouse

When making a small number of parts, the economics of legacy manufacturing methods don’t always add up. ClarinetXpress frequently needs a relatively low volume of mouthpieces, comprising several different types and sizes. Where legacy processes would likely require them to order a large minimum number of each mouthpiece, additive allows them to order only as many as needed, without incurring extra cost. This approach creates a Virtual Warehouse™ for ClarinetXpress; instead of ordering mouthpieces in bulk and storing them, they can now place orders for small batches to meet immediate demand.

Gallery

THE RESULTS

A long-term solution for quickly and reliably producing high-quality, customized clarinet mouthpieces

Faster

Prototyping

Enhanced

Reliability and repeatability

Greater

Customization

Ready to make your parts with Fast Radius?

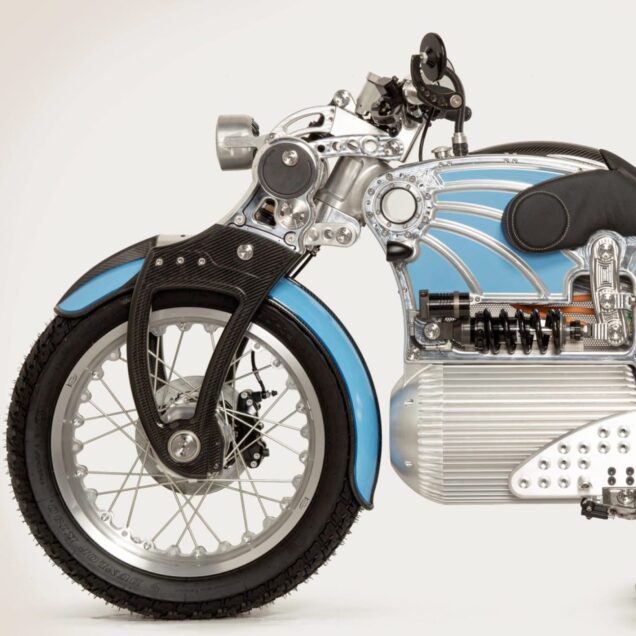

Making disruptive design possible

Working with Fast Radius allowed us to explore what’s now possible – we were able to identify, design, and produce a real end-use product with additive.

The challenge

Unlocking new designs and mass customization

Steelcase had big plans to reimagine its successful chair design using innovative manufacturing processes.

Steelcase wanted to expand the personalization options on its SILQ chair. To further differentiate the product and improve the development process they turned to additive manufacturing — and found a partner in Fast Radius.

Breakthroughs often start with a simple concept. And in the case of Steelcase’s SILQ chair — which won a prestigious Innovation Award at the 2018 NeoCon — an aspirational sketch started it all.

In 2008, James Ludwig, Vice President of Global Design & Engineering at Steelcase™, sketched a chair concept stripped of all the machinery that had become status quo in high-performance seating. Since SILQ first debuted, Steelcase has continued to experiment with enhancements to the chair’s design, living up to its decades-old reputation of pursuing innovation. Now, consumers can personalize their chair with different fabrics, colors or finishes.

Steelcase joined Fast Radius’s Application Launch Program® (ALP) in January 2018 to find an additive application that went beyond using production-grade 3D printing as a tool for rapid prototyping. They wanted to explore how additive manufacturing could improve the product development process and differentiate their products in the market, while also greatly reducing the time it took to bring their products to life. The team decided to partner with Fast Radius and use Carbon® to design, engineer and print a custom arm cap using digital manufacturing.

To capture innovation awards, earn press and make waves, you have to be first. It’s only natural that Steelcase is adopting additive manufacturing as a means of enhancing design and streamlining production. And the impact transcends the SILQ chair. It transcends even the furniture industry. It means that designs that were unmakeable 10 years ago have been made possible with the advent of scalable, production-grade additive manufacturing.

Ever since SILQ first debuted, we have continued to experiment with enhancements to the chair’s design, living up to our reputation of pursuing innovation. The additive manufacturing processes from Fast Radius and Carbon enabled us to streamline the already-unique aesthetics of the chair with a lattice structure that also condensed three parts into one.

making it possible

Expedited development and real-time prototyping

1. Streamlined product design and development

A key benefit of additive manufacturing is expedited speed to production. In each design iteration, the prototypes were at nearly production-grade levels. Not only did this save Steelcase time in the design and prototyping phases, but it also allowed them to glean insights about fit, form and functionality in real time. This allowed greater improvements to the design that may not have been realized with traditional prototyping — and for a design-driven company like Steelcase, this was crucial. Steelcase could go through as many redesign cycles as it took to get things right. In this instance, Fast Radius took the initial idea and turned it into 100 design concepts. From those iterations, Fast Radius produced 12 unique designs in just six weeks.

2. Improved aesthetics

Carbon’s Digital Light Synthesis™ (DLS) technology uniquely enabled Steelcase and Fast Radius to experiment with design of lattice structures, textures, multi-durometer foam replacement and other functional elements. In the end, an aesthetic lattice structure and unique texture were incorporated into the design of the arm cap to allow the part to stand out and showcase its additive origins.

3. Part consolidation

Every part of the SILQ chair responds to gestural inputs rather than manual adjustments, reacting intuitively to a person’s body and movements. The arm cap was no exception. SILQ arm caps were traditionally manufactured with three separate parts assembled together. Using additive manufacturing, Fast Radius printed the arm cap as one contiguous unit — no assembly required.

4. Material reduction

Fast Radius also designed the arm cap in four zones that provided different attributes based on how someone’s arm might interact with the cap. Although each zone was designed separately, Carbon’s DLS technology allowed the entire arm cap to be printed as one cohesive part using EPU 41, a material that is both flexible and conforming. And the use of lattices reduced material usage by up to 70% without sacrificing performance.

5. Zero-cost mass customization

Consumer personalization is fundamental to the SILQ idea. For high-value products like this, mass customization can be a key differentiator. More than three-quarters of consumers are willing to pay a premium for customized furniture. If a corporate client wanted to personalize the arm cap by changing the texture, adding a logo or customizing the look of the exposed lattice, it’s simply a design change in the CAD file. And when the part phases out of production — or a client wants to do another run of their custom arm cap — the CAD files can still be printed on demand. No re-tooling, no warehouse costs. Just change, print and go.

Gallery

the results

A disruptive design and innovation partnership opening the door to transforming an industry

100

design concepts produced by Fast Radius

12

unique designs produced and tested in 6 weeks

70%

reduced material usage in the final product

Back

Back