Making faster factories possible

Colgate needed to improve efficiency on a bottling line where a malfunctioning part was causing stoppages and waste. Fast Radius working closely with Colgate’s engineers designed a solution that relied on two additive technologies, resulting in reduced unplanned downtime and greater production throughput.

THE CHALLENGE

Reducing downtime on a busy factory line

In order to keep production running at full capacity, Colgate needed an inventive fix for an ineffective piece of machinery.

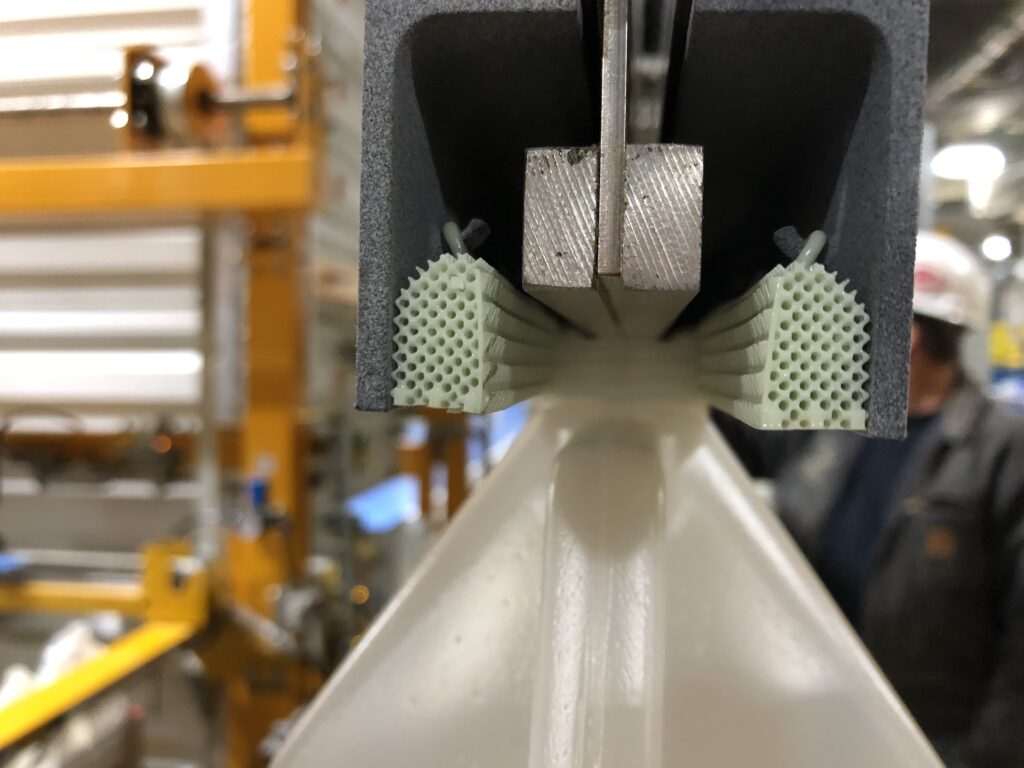

Colgate had a bottle accumulator that was not running efficiently. Unexpected failures occurred with a rigid plastic part that was meant to hook a very small ridge on each bottle, lift the bottles, and move them onto the line. The tool frequently missed the ridge, dropping bottles onto the factory floor.

Without a functional bottle accumulator, bottles would accumulate and back up the line, which led to frequent stops and starts that resulted in costly downtime. To tackle this problem, Colgate came to the Fast Radius design engineering team for help designing and producing better tooling that would work with their existing bottle accumulator. By using additive manufacturing, they were able to get the machine back in service quickly.

Before we did this work with Fast Radius, the utilization of our bottle accumulator was near zero. With the new gripper designs, the machine is now set to run 100% of the time.

MAKING IT POSSIBLE

Flexible materials and real-world testing

1. Design for additive manufacturing (DfAM)

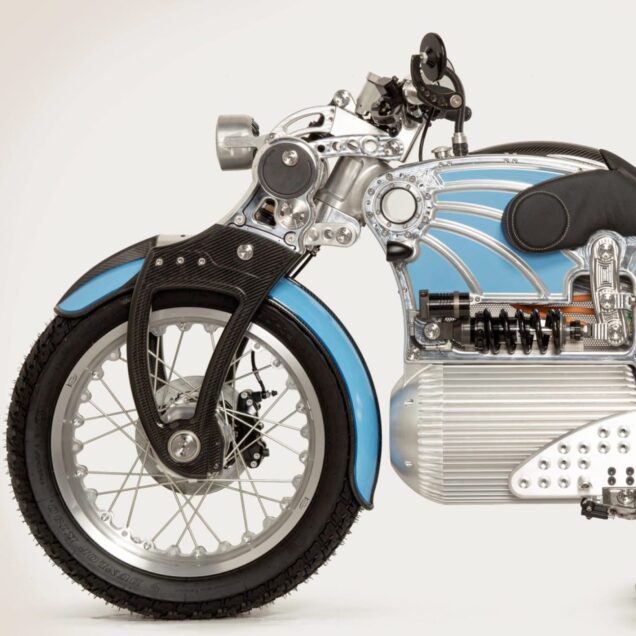

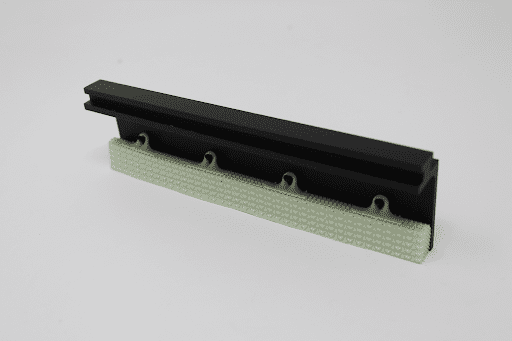

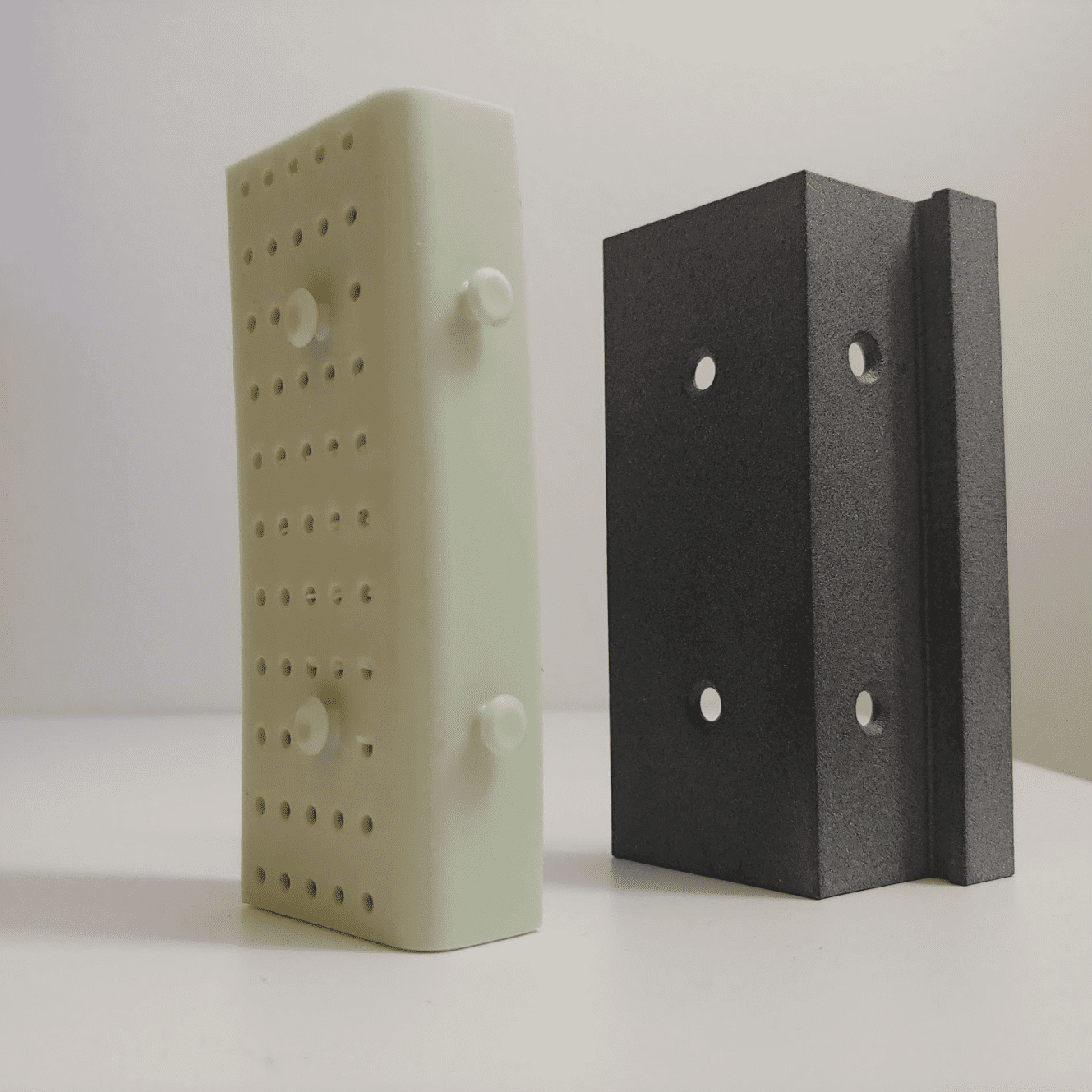

Fast Radius designed the gripper in two parts, each made with a different additive process. Printed in durable PA 12 using HP MJF technology, the outer portion of the part slides into the metal bottling conveyor and supports the weight of the bottles. The inner portion of the tool is a flexible lattice mesh printed with Carbon’s highly resilient elastomeric polyurethane material, EPU 41,using the Carbon Digital Light Synthesis™ (Carbon DLS™) process. Fast Radius engineers designed a lattice structure that easily conformed to different shapes, meaning it could get a strong grip on bottles of various sizes. While the previous tool needed to be changed out every time Colgate switched between bottle types, the new gripper can be used to pick multiple bottle sizes.

2. High-performance materials

In an industrial setting, it’s crucial to be able to change parts quickly with as few tools as possible for maximum efficiency and minimal downtime. To accomplish this, Fast Radius and Colgate took advantage of the material properties of PA 12 and EPU 41 to design a two-component part that assembles without any fasteners. The EPU 41 inner portion of the bottle gripper seamlessly wraps around and hooks into the strong PA 12 outer portion for a secure assembly. Together the two materials provide the flexibility and strength required to pick up and move bottles without dropping them.

3. Multi-process manufacturing

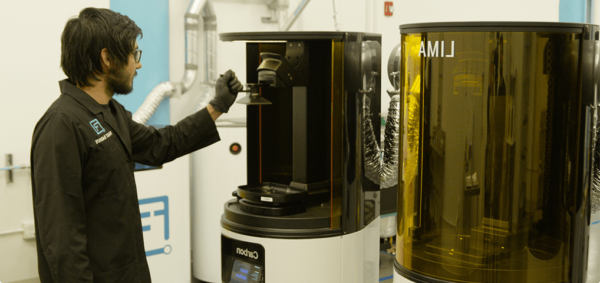

Fast Radius offers multiple manufacturing technologies under one roof, so they were able to make and assemble Colgate’s parts easily, even though the parts required different processes. Colgate didn’t have to worry about coordinating different suppliers, and they didn’t have to invest in their own additive manufacturing equipment. Beyond access to Fast Radius’ Carbon DLS and HP MJF factories, Colgate was able to work with Fast Radius engineers who are experts in DfAM and identifying the right process for each project.

4. Testing in a production environment

Fast Radius and Colgate went through three design iterations to perfect the bottle gripper. Because additive manufacturing allows you to prototype using the same equipment and materials that will be used in the final parts, Colgate was able to test each prototype directly on the bottling line in real working conditions. These tests provided invaluable insight into the performance of the part and made it easy to identify the adjustments needed. Once Colgate accepted the design, the parts were produced immediately and put to work on the line.

The Results

A small part that made a big difference

100%

production capacity

Flexible

Bottle handling

Restored

Operator confidence in machine

Gallery

Ready to make your parts with Fast Radius?

Making sustainable manufacturing possible

Husqvarna Group wanted to streamline their spare parts supply chain and reduce their carbon footprint. Fast Radius made it possible with additive manufacturing and a Virtual Warehouse™.

The challenge

Transforming the supply chain with additive manufacturing

The Fast Radius team worked with Husqvarna Group to identify spare parts that could be made more efficiently and sustainably through additive manufacturing — driving a reduced carbon footprint, improved customer experience and lower costs.

Husqvarna Group, based in Sweden, is a global leader in outdoor power products for forest, park and garden care that has a 300-year history of producing high-quality, leading-edge products. One of the reasons Husqvarna Group has remained successful for so long is its ability to evolve with shifting technology and customer demands.

When 3D printing began to reach production-grade levels, Husqvarna Group naturally wanted to explore how an advanced manufacturing approach could drive impact for their business. They partnered with Fast Radius to make it possible.

Additive manufacturing lowered costs, improved customer experience and reduced Husqvarna’s carbon footprint.

Making it possible

Part validation and supply chain transformation

1. Identifying parts and manufacturing methods

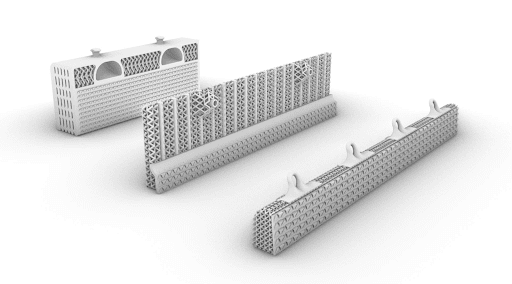

Fast Radius’s application engineers collaborated with Husqvarna Group to identify parts they could produce reliably at scale with additive manufacturing. Once the parts were selected, Fast Radius drew on extensive expertise in additive technologies to determine the best way to make the parts based on cost and performance requirements. HP Multi Jet Fusion (MJF) and Carbon® Digital Light Synthesis™ (DLS) were chosen as the ideal technologies for handling Husqvarna Group’s broad range of parts.

2. Part approval process

Once the teams identified families of parts that could be produced additively, they needed to validate the parts’ performance and durability to certify them for production and sale. This meant performing UV resistance tests, chemical resistance tests, days-long cycle tests and ultimately evaluating real-world performance in the field. The end result is a rigorous Production Part Approval Process (PPAP) that enables Husqvarna Group and Fast Radius to reliably make existing parts and onboard new ones.

3. Virtual Warehousing

After parts pass Husqvarna Group’s PPAP, the designs and production specifications are stored digitally in the Fast Radius Virtual Warehouse, meaning parts can be made on demand when they’re needed in any quantity. This eliminates the supply chain costs associated with traditional manufacturing including tooling, warehousing, high minimum order quantities, material waste and part obsolescence.

4. Enhancing the customer experience

The Virtual Warehouse enables a better experience for Husqvarna’s customers, too. With traditional manufacturing, if a customer needs a part that isn’t readily available, replenishment can take weeks. Even worse, parts for older products might not be available at all if they’ve reached “end of life.” Now, when a Husqvarna Group customer needs a replacement part that’s hosted in the Fast Radius Virtual Warehouse, Fast Radius can produce and deliver the part in a matter of days. The part will never be out of stock again, giving peace of mind to Husqvarna Group’s end customers.

5. Sustainable manufacturing solutions

Additive manufacturing is an element in Husqvarna Group’s sustainability program, “Sustainovate,” which establishes publicly recognized and testified CO2 reduction targets for the year 2035. Unlike traditional manufacturing processes, which require high minimum order quantities, additive allows for economical production in units as small as one. Because of this, Husqvarna Group can produce only as many parts as their customers need at a time — no more, no less — resulting in less material waste, no obsolete parts and a lower carbon footprint.

Gallery

The results

An efficient and sustainable supply chain made possible by additive manufacturing and a virtual warehouse

Reduced

carbon footprint

Enhanced

customer experience

Eliminated

inventory carry costs

Back

Back